loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

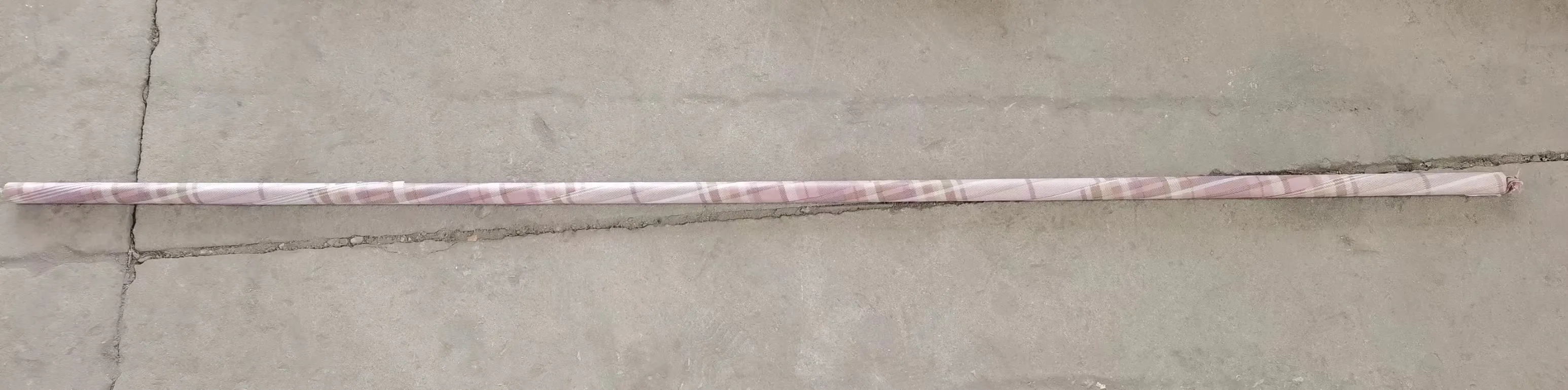

1054 frp vessel

Understanding the 1054% FRP Vessel A Breakthrough in Composite Technology

In the realm of modern engineering and materials science, the development of composite materials has revolutionized various industries, notably marine, automotive, and aerospace. One of the standout innovations within this space is the 1054% FRP (Fiberglass Reinforced Plastic) vessel, an extraordinary advancement that combines strength, durability, and versatility.

What is 1054% FRP?

The term 1054% FRP vessel refers to a fiberglass reinforced plastic container designed to withstand extreme conditions while maintaining structural integrity. The 1054% signifies the enhanced performance metrics attributed to the use of advanced production techniques and superior resin systems. This particular FRP vessel is engineered to exceed conventional capacities found in traditional materials, offering a unique solution for various applications.

Advantages of FRP Vessels

1. Corrosion Resistance One of the most significant advantages of FRP vessels is their exceptional resistance to corrosion. Unlike metal containers, which can degrade when exposed to harsh chemicals or environmental conditions, FRP vessels maintain their integrity over time, reducing maintenance costs and increasing service life.

2. Lightweight FRP vessels are significantly lighter than their metallic counterparts. This characteristic not only facilitates easier handling during shipping and installation but also contributes to reduced energy consumption when used in transportation applications.

3. High Strength-to-Weight Ratio Despite being lightweight, FRP materials offer a high strength-to-weight ratio, making them capable of handling substantial pressures and loads. This property is essential for applications requiring robust performance without compromising on weight.

1054 frp vessel

4. Design Flexibility The manufacturing process of FRP allows for intricate designs and shapes that can be tailored to specific requirements. This versatility enables engineers and designers to create vessels that meet unique operational needs without the limitations imposed by traditional materials.

5. Thermal Insulation FRP vessels provide excellent thermal insulation properties, making them suitable for various temperature-sensitive applications. This quality is particularly valuable in industries where maintaining temperature is crucial, such as food and pharmaceuticals.

Applications of 1054% FRP Vessels

The versatility of 1054% FRP vessels makes them ideal for a myriad of applications. In the marine industry, they are used for fuel tanks, hulls, and various other components where weight and corrosion resistance are critical. In the chemical industry, these vessels serve as storage tanks for reactive substances, effectively preventing leaks and ensuring safety.

Moreover, FRP vessels are increasingly utilized in wastewater treatment facilities, offering durability and resistance to aggressive treatments used in the purification process. In agriculture, they can store fertilizers and other chemicals, environmentally safeguarding against contamination.

Conclusion

The 1054% FRP vessel exemplifies the outstanding possibilities presented by modern composite materials. With its robust properties, lightweight nature, and resistance to environmental factors, it offers an innovative solution to many industries facing the challenges of traditional materials. As technology continues to develop, we can expect FRP vessels to play an even more significant role in various applications, contributing to efficiency and sustainability across different sectors. Embracing innovations like the 1054% FRP vessel positions industries for a future characterized by enhanced performance and reduced environmental impact.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024