loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1054 frp vessel

The Significance of a 1054% FRP Vessel in Modern Engineering

In today's rapidly advancing technological landscape, the need for innovative materials and designs in engineering has never been more critical. One such innovation is embodied in the concept of a 1054% FRP (Fiber Reinforced Polymer) vessel. Understanding the significance of such vessels requires a deep dive into the characteristics of FRP, its applications, and the implications of its implementation in various industries.

What is FRP?

Fiber Reinforced Polymer is a composite material made of a polymer matrix combined with fibers, such as glass, carbon, or aramid. The unique properties of FRP, such as high strength-to-weight ratio, corrosion resistance, and design flexibility, make it an ideal material for constructing vessels and other structural elements subjected to various environmental and mechanical stresses. The term 1054% FRP vessel could refer to a specific design or a project where the FRP content is optimized beyond the conventional levels, ensuring enhanced performance and durability.

Key Properties of FRP

1. Lightweight One of the most significant advantages of FRP is its lightweight nature. Vessels constructed from FRP are considerably lighter than their metal counterparts, which translates to lower transportation costs and easier handling during installation.

2. Corrosion Resistance Unlike traditional materials such as steel or aluminum, FRP does not corrode when exposed to different environmental conditions. This feature is particularly beneficial in industries like marine, chemical, and wastewater management, where vessels are regularly exposed to corrosive substances.

3. High Strength Despite its lightweight nature, FRP exhibits exceptional strength, allowing it to withstand high pressures and extreme conditions. This property is crucial for vessels that operate under demanding circumstances, such as high-temperature environments or under significant stress.

4. Design Flexibility FRP can be molded into various shapes and sizes, making it easier to design custom vessels tailored to specific applications. This flexibility enables engineers to create innovative solutions that meet unique project requirements.

1054 frp vessel

Applications of FRP Vessels

The versatility of FRP vessels makes them suitable for a wide range of applications across numerous industries.

1. Marine Applications In the marine industry, FRP vessels are commonly used for constructing boats, ship hulls, and floating platforms. Their resistance to saltwater corrosion enhances the longevity of marine structures.

2. Chemical Processing In chemical manufacturing, FRP vessels are preferred for storing and transporting corrosive chemicals. Their ability to withstand harsh environments helps maintain process integrity and safety.

3. Wastewater Management FRP is increasingly utilized in wastewater treatment facilities. The durability and corrosion resistance of FRP vessels ensure effective treatment processes without the risk of material degradation.

4. Aerospace and Defense The aerospace sector benefits from the lightweight and strong properties of FRP. It is used in various components and structures, contributing to fuel efficiency and performance enhancement.

Conclusion

The development of a 1054% FRP vessel marks a significant advancement in engineering and materials science. With its remarkable properties and diverse applications, FRP offers solutions to some of the most pressing challenges faced by modern industries. The focus on optimizing the performance of FRP vessels indicates a commitment to sustainability, efficiency, and innovation in engineering practices.

As industries continue to evolve, the role of advanced materials like FRP will undoubtedly expand, paving the way for new possibilities in design and application. The 1054% FRP vessel stands as a testament to human ingenuity and a step towards a more resilient future in engineering. The continued exploration and implementation of such technology are crucial in addressing the demands of an ever-changing world, ensuring safety, reliability, and performance across various sectors.

-

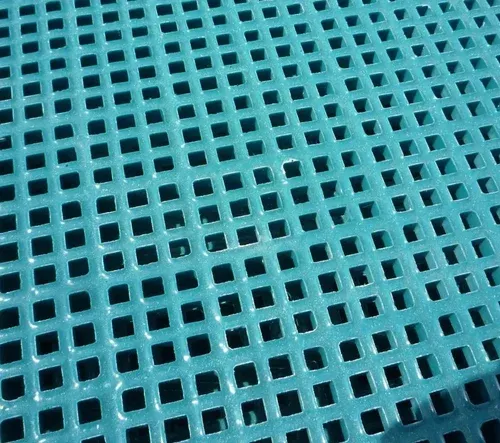

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024