loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 15, 2025 00:02

Back to list

1054 frp vessel

In the field of industrial applications, choosing the right material and equipment can make or break the productivity and safety of an operation. For many businesses, 1054 FRP (Fiberglass Reinforced Plastic) vessels have become an integral part of their process infrastructure, offering benefits that traditional materials simply cannot match. This article delves into the unique advantages and applications of 1054 FRP vessels, establishing their role as a trusted solution in today's demanding environments.

The versatility of 1054 FRP vessels is evidenced by their widespread application across diverse sectors. In the water treatment industry, they serve as storage tanks for chlorine, fluoride, and other chemicals, ensuring a safe supply of potable water. In the realm of industrial processing, these vessels hold and transport chemicals critical to production lines. Additionally, the food and beverage industry trusts FRP vessels for the storage of edible products, taking advantage of their non-reactive characteristics to protect product quality. Experts in the field underline the reliability and longevity of 1054 FRP vessels. With decades of proven performance in rigorous applications, these vessels have earned their reputation not only for robustness but also for safeguarding operational integrity. Their integration into safety-critical applications—such as upstream oil and gas operations—underscores the confidence that industries place in FRP technology. Trustworthiness and credibility are fundamental when choosing an industrial solution, and the track record of 1054 FRP vessels speaks volumes. Manufacturers support their products with comprehensive warranties and service agreements, offering peace of mind that spans many years of operation. Additionally, third-party certifications and compliance with industry standards further affirm the quality and dependability of these vessels. In conclusion, the strategic advantages offered by 1054 FRP vessels make them an invaluable asset in industrial applications where safety, reliability, and efficiency are non-negotiable. By combining durability with customization and environmental benefits, they represent a sophisticated solution for modern industrial challenges. Selecting 1054 FRP vessels is not merely a choice of material but an investment in the future of your operations. Businesses that integrate these vessels can expect not only enhanced performance but also a significant return on investment through reduced maintenance and operational costs.

The versatility of 1054 FRP vessels is evidenced by their widespread application across diverse sectors. In the water treatment industry, they serve as storage tanks for chlorine, fluoride, and other chemicals, ensuring a safe supply of potable water. In the realm of industrial processing, these vessels hold and transport chemicals critical to production lines. Additionally, the food and beverage industry trusts FRP vessels for the storage of edible products, taking advantage of their non-reactive characteristics to protect product quality. Experts in the field underline the reliability and longevity of 1054 FRP vessels. With decades of proven performance in rigorous applications, these vessels have earned their reputation not only for robustness but also for safeguarding operational integrity. Their integration into safety-critical applications—such as upstream oil and gas operations—underscores the confidence that industries place in FRP technology. Trustworthiness and credibility are fundamental when choosing an industrial solution, and the track record of 1054 FRP vessels speaks volumes. Manufacturers support their products with comprehensive warranties and service agreements, offering peace of mind that spans many years of operation. Additionally, third-party certifications and compliance with industry standards further affirm the quality and dependability of these vessels. In conclusion, the strategic advantages offered by 1054 FRP vessels make them an invaluable asset in industrial applications where safety, reliability, and efficiency are non-negotiable. By combining durability with customization and environmental benefits, they represent a sophisticated solution for modern industrial challenges. Selecting 1054 FRP vessels is not merely a choice of material but an investment in the future of your operations. Businesses that integrate these vessels can expect not only enhanced performance but also a significant return on investment through reduced maintenance and operational costs.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

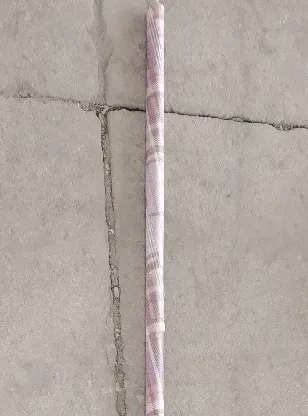

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024