loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1665 frp vessel price

Understanding the Pricing of 1665 FRP Vessels

In recent years, the demand for Fiber Reinforced Plastic (FRP) vessels has surged across various industries due to their unique properties, including corrosion resistance, lightweight structure, and durability. Among the different models available, the 1665 FRP vessel has garnered attention for its versatility and performance. In this article, we will explore factors influencing the pricing of the 1665 FRP vessel, its advantages, and the implications for industries reliant on such technologies.

What are FRP Vessels?

FRP vessels are composite materials made from a polymer matrix reinforced with fibers. This combination results in materials that are significantly lighter than traditional metals but offer superior strength and resistance to a variety of environmental factors. The 1665 model specifically refers to a particular size and configuration of these vessels, commonly utilized in chemical storage, water treatment, and marine applications.

Factors Affecting the Price of 1665 FRP Vessels

1. Material Composition The type and quality of the fibers and resin used in the construction of the 1665 FRP vessels directly impact pricing. Higher-grade materials generally result in improved performance characteristics, such as better chemical resistance and thermal stability, which can justify a higher price.

2. Manufacturing Process The method of manufacturing the vessel plays a critical role in determining its cost. Processes such as hand layup, vacuum infusion, or filament winding each have different cost implications. Automated processes may reduce labor costs but could require a higher initial investment in equipment.

3. Customization and Design FRP vessels are often tailored to meet specific industry requirements, which can involve unique design features or modifications. Customization can significantly increase the overall price due to extended production times and the need for specialized engineering.

1665 frp vessel price

4. Market Demand Like any commodity, the price of the 1665 FRP vessel is influenced by market demand. In industries where the need for corrosion-resistant materials is growing—such as wastewater management or oil and gas—the prices may experience upward pressure due to increased competition and limited supply.

5. Transportation and Installation Costs FRP vessels may need to be shipped considerable distances depending on the manufacturing location and the end-user's site. The costs associated with transportation, installation, and any necessary modifications on-site can also add to the overall expenditure.

Benefits of Using 1665 FRP Vessels

Investing in 1665 FRP vessels comes with numerous benefits that can outweigh the initial costs. Their lightweight nature allows for easier handling and installation, reducing labor costs and time. Additionally, their resistance to corrosion minimizes maintenance expenses and extends the lifespan of the vessel, making them a cost-effective long-term solution.

Moreover, the versatility of FRP vessels makes them suitable for various applications, such as chemical processing, water treatment, and even in the food industry, where hygiene and corrosion resistance are paramount. This versatility can open new market opportunities for businesses, further justifying the investment in these advanced materials.

Conclusion

The pricing of the 1665 FRP vessel is influenced by multiple factors ranging from material quality to market demand. While the initial cost may appear substantial, the long-term benefits, including reduced maintenance, enhanced durability, and operational efficiency, offer significant returns on investment. As industries continue to look for sustainable and efficient alternatives, the 1665 FRP vessel stands as a premier choice, symbolizing a blend of technology and practical application that meets modern industrial challenges.

-

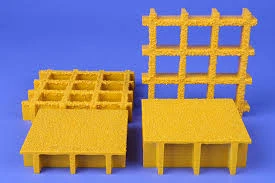

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024