loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 15, 2025 01:15

Back to list

1665 frp vessel price

The industrial landscape continually evolves, and with it, the need for innovative and reliable storage solutions becomes critical. When businesses seek durable, acid-resistant, and cost-effective storage options, FRP (Fiber Reinforced Plastic) vessels often emerge as a leading choice. However, understanding the pricing of FRP vessels can be a complex endeavor, as costs fluctuate based on several variables. This article delves into the pivotal factors determining the price of a 1665 FRP vessel, embodying a blend of real experience and expert opinion, aimed at offering authoritative insights and trustworthy guidance.

Transportation and installation costs also contribute significantly to the final price tag of a 1665 FRP vessel. The weight-saving benefits of FRP reduce transportation costs compared to conventional materials. Still, logistical factors such as distance, complexity of the installation site, and required installation equipment can add unforeseen expenses. Selecting a supplier with a proven track record in seamless delivery and installation can mitigate additional costs and risks. Market demand and macroeconomic factors, including global supply chain dynamics and raw material availability, undeniably influence FRP vessel pricing as well. Disruptions in the supply chain or shifts in demand may affect raw material prices, compelling upward price adjustments. Hence, keeping abreast of such market trends is crucial for those anticipating future purchases of FRP vessels. Partnering with an informed supplier who monitors and navigates these market conditions can provide a strategic advantage, securing favorable pricing over time. Finally, warranty, maintenance, and after-sales service can add to the perceived value and ultimate cost of an FRP vessel. While initial investment considerations are major factors, the long-term reliability and ease of maintenance afforded by the chosen vessel can lead to substantial cost savings. Manufacturers with extensive support systems and favorable warranty terms might offer slightly higher upfront pricing, yet provide undeniable value through enhanced durability and post-purchase support, underlining the necessity to evaluate these aspects carefully. Embracing the shift towards sustainable and innovative materials necessitates not only scrutinizing the product performance but comprehensively understanding all economic implications associated with procurement. A detailed assessment of material quality, customization, logistics, market conditions, and supporting services forms the foundation for an informed and economically sound acquisition of a 1665 FRP vessel. As industries progressively venture into utilizing FRP technology, discerning engagement with expert partners will establish the balance between requisite performance and financial prudence.

Transportation and installation costs also contribute significantly to the final price tag of a 1665 FRP vessel. The weight-saving benefits of FRP reduce transportation costs compared to conventional materials. Still, logistical factors such as distance, complexity of the installation site, and required installation equipment can add unforeseen expenses. Selecting a supplier with a proven track record in seamless delivery and installation can mitigate additional costs and risks. Market demand and macroeconomic factors, including global supply chain dynamics and raw material availability, undeniably influence FRP vessel pricing as well. Disruptions in the supply chain or shifts in demand may affect raw material prices, compelling upward price adjustments. Hence, keeping abreast of such market trends is crucial for those anticipating future purchases of FRP vessels. Partnering with an informed supplier who monitors and navigates these market conditions can provide a strategic advantage, securing favorable pricing over time. Finally, warranty, maintenance, and after-sales service can add to the perceived value and ultimate cost of an FRP vessel. While initial investment considerations are major factors, the long-term reliability and ease of maintenance afforded by the chosen vessel can lead to substantial cost savings. Manufacturers with extensive support systems and favorable warranty terms might offer slightly higher upfront pricing, yet provide undeniable value through enhanced durability and post-purchase support, underlining the necessity to evaluate these aspects carefully. Embracing the shift towards sustainable and innovative materials necessitates not only scrutinizing the product performance but comprehensively understanding all economic implications associated with procurement. A detailed assessment of material quality, customization, logistics, market conditions, and supporting services forms the foundation for an informed and economically sound acquisition of a 1665 FRP vessel. As industries progressively venture into utilizing FRP technology, discerning engagement with expert partners will establish the balance between requisite performance and financial prudence.

Share

Next:

Latest news

-

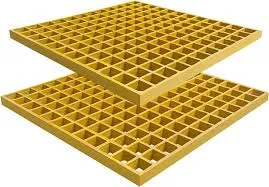

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024