loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2472 frp vessel

Exploring the Advancements in 2472 FRP Vessels

In recent years, the adoption of Fiber Reinforced Plastic (FRP) materials in vessel manufacturing has gained substantial momentum. One notable example is the 2472 FRP vessel, which represents a significant advancement in both the design and application of composite materials in various industries. These vessels are being utilized in a myriad of applications, from water treatment and chemical storage to oil and gas sectors, owing to their unique properties and advantages over traditional materials.

FRP vessels are constructed using a combination of fiberglass and resin, which provides a lightweight yet highly durable and corrosion-resistant structure. The 2472 designation signifies specific dimensions or configurations tailored for specialized applications, optimizing both performance and ergonomic factors. One of the foremost benefits of using FRP for vessels is their resistance to corrosion. Unlike metal materials that can rust and corrode when exposed to harsh chemicals or environmental factors, FRP vessels maintain structural integrity over time, ensuring a longer lifespan and reduced maintenance costs.

Exploring the Advancements in 2472 FRP Vessels

The manufacturing process of FRP vessels involves advanced techniques such as filament winding, which allows for precise control over the fiber orientation and resin application. This precision leads to enhanced mechanical properties, making these vessels capable of withstanding high pressures and temperatures. As a result, 2472 FRP vessels are increasingly being utilized in high-stakes environments where conventional materials may falter.

2472 frp vessel

The environmental impact of vessel manufacturing and usage is an increasingly critical consideration in today’s market. FRP vessels tend to have a lower carbon footprint during their life cycle compared to their metal counterparts. Additionally, their durability and resistance to chemical degradation mean that they can often be used longer without needing replacement, aligning with sustainability goals that many industries are striving to achieve.

Furthermore, the design flexibility afforded by FRP composites allows for the creation of customized solutions that meet specific operational requirements. The ability to mold FRP into complex shapes opens up avenues for innovative designs that can further enhance functionality and efficiency in various applications. Customization options not only improve performance but can also lead to aesthetically pleasing designs that fit seamlessly into modern industrial settings.

As industries continue to evolve, the integration of advanced materials like the 2472 FRP vessel will likely expand. Research and development in the field of composite materials are ongoing, which may lead to even more robust formulations and applications. Innovations such as self-healing polymers and enhanced fiber technologies are on the horizon, which could further revolutionize the use of FRP vessels.

In conclusion, the 2472 FRP vessel exemplifies the remarkable potential of composite materials in various industries. With their combination of lightweight strength, corrosion resistance, and design flexibility, these vessels are not only addressing the current demands of industrial applications but are also paving the way for a more sustainable future. As the technology continues to advance, we can expect to see the proliferation of FRP solutions that optimize performance while minimizing environmental impact, ensuring their place as a cornerstone in the evolution of vessel manufacturing.

-

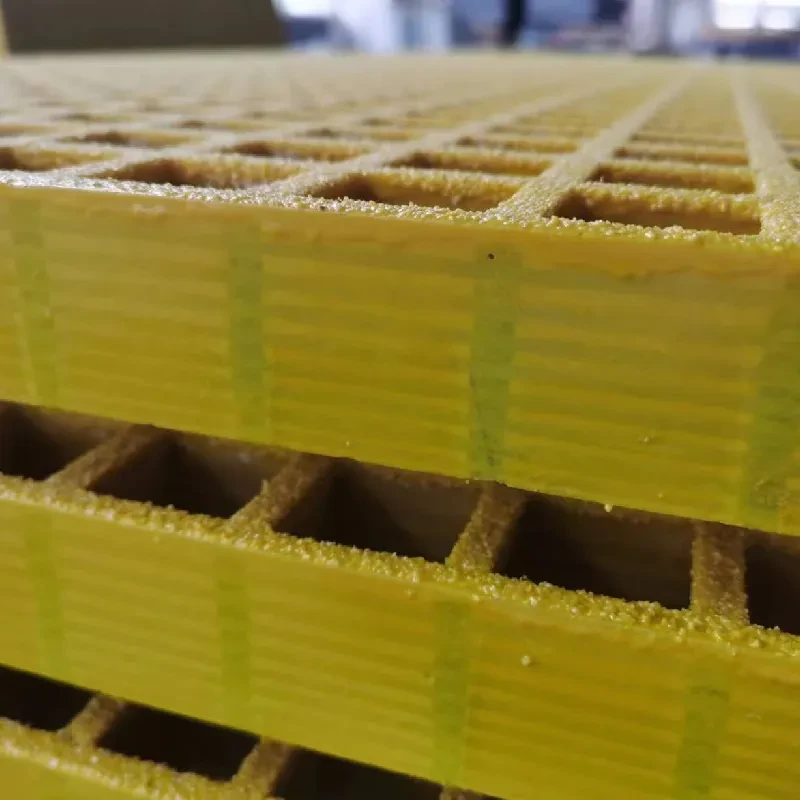

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024