loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2472 frp vessel

Exploring the Capabilities of 2472% FRP Vessels

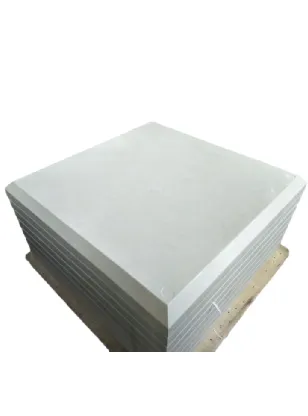

In recent years, the demand for advanced materials in various industries has significantly increased. One of the most innovative solutions that has gained substantial attention is the Fiber Reinforced Polymer (FRP) vessel, particularly the 2472% FRP vessel. This cutting-edge technology is revolutionizing the way we approach containment and storage solutions across multiple sectors, particularly in chemical, marine, and infrastructure applications.

Exploring the Capabilities of 2472% FRP Vessels

The construction of a 2472% FRP vessel involves the use of advanced composite materials, combining fibers (usually glass or carbon) with a polymer matrix. This composite structure not only provides high strength but also keeps the vessel lightweight, which is crucial for ease of transportation and installation. Such properties have made FRP vessels particularly popular in industries that require the storage and transport of corrosive chemicals, where safety and durability are of utmost importance.

2472 frp vessel

Further, the 2472% FRP vessels are increasingly being adopted in marine applications. Their lightweight nature allows for increased fuel efficiency in shipping and boating, while their resistance to saltwater and harsh weather conditions ensures minimal maintenance and extended service life. This is especially relevant for offshore platforms and vessels operating in extreme marine environments, where equipment failure can lead to significant financial losses and safety hazards.

In addition to their mechanical properties, 2472% FRP vessels can be designed with various custom features, such as thermal insulation or additional layers for enhanced safety. These vessels can also be equipped with monitoring systems to track internal conditions, providing real-time data on pressure and temperature, thereby ensuring optimal operational parameters.

The future of 2472% FRP vessels looks promising, with ongoing research focused on enhancing their capabilities even further. Innovations in manufacturing techniques and material science are paving the way for even more efficient and cost-effective solutions. As industries continue to seek sustainable and durable alternatives, FRP vessels will undoubtedly play a pivotal role in meeting these demands.

In conclusion, the 2472% FRP vessel represents a significant advancement in containment technology, offering unmatched strength, corrosion resistance, and lightweight properties. Its applications span across various industries, providing solutions that enhance safety and efficiency. As technology progresses, we can expect these vessels to become even more integral to modern infrastructure and industrial practices.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024