loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 15, 2025 01:54

Back to list

frp vessel for water treatment

In the industrial sector, materials play a critical role in ensuring safety, efficiency, and longevity of equipment. Fiberglass Reinforced Plastic (FRP) vessels have gained prominence due to their superior characteristics, especially in environments that require resistance to corrosive substances. Delving into the nuances of 2472 FRP vessels reveals a world where materials science aligns seamlessly with industrial needs.

The expertise behind 2472 FRP vessel fabrication involves advanced techniques in resin and fiber technology. Expert fabricators employ high-quality resins and precisely aligned fibers to optimize the mechanical properties of each vessel. This craftsmanship ensures that each vessel meets rigorous industry standards and provides reliable performance over its operational lifespan. In terms of authoritativeness, manufacturers of 2472 FRP vessels often adhere to internationally recognized standards such as ASME RTP-1, which delineates the requirements for fiberglass reinforced thermoset plastic corrosion-resistant equipment. Compliance with such standards ensures that these vessels not only meet but often exceed customer expectations in performance and safety. Building trustworthiness in 2472 FRP vessels is achieved through rigorous testing and certification. Manufacturers typically conduct thorough inspections involving pressure tests, temperature resilience checks, and corrosion resistance verifications. These assessments confirm that each vessel is fit for purpose and ready to withstand the challenges of its intended industrial application. End users of 2472 FRP vessels share numerous positive testimonials regarding their effectiveness and reliability. Industries report significant savings in maintenance and replacement costs, as well as improvements in operational efficiency due to the reduced need for downtime. These experiences highlight the tangible benefits that FRP vessels bring to industrial operations and underscore their growing popularity in a competitive market. In conclusion, 2472 FRP vessels are not merely an industrial product but represent a blend of scientific innovation, expert engineering, and reliable performance. Their unique properties and customization possibilities make them an invaluable asset across various sectors, promoting safety, efficiency, and sustainability in industrial applications.

The expertise behind 2472 FRP vessel fabrication involves advanced techniques in resin and fiber technology. Expert fabricators employ high-quality resins and precisely aligned fibers to optimize the mechanical properties of each vessel. This craftsmanship ensures that each vessel meets rigorous industry standards and provides reliable performance over its operational lifespan. In terms of authoritativeness, manufacturers of 2472 FRP vessels often adhere to internationally recognized standards such as ASME RTP-1, which delineates the requirements for fiberglass reinforced thermoset plastic corrosion-resistant equipment. Compliance with such standards ensures that these vessels not only meet but often exceed customer expectations in performance and safety. Building trustworthiness in 2472 FRP vessels is achieved through rigorous testing and certification. Manufacturers typically conduct thorough inspections involving pressure tests, temperature resilience checks, and corrosion resistance verifications. These assessments confirm that each vessel is fit for purpose and ready to withstand the challenges of its intended industrial application. End users of 2472 FRP vessels share numerous positive testimonials regarding their effectiveness and reliability. Industries report significant savings in maintenance and replacement costs, as well as improvements in operational efficiency due to the reduced need for downtime. These experiences highlight the tangible benefits that FRP vessels bring to industrial operations and underscore their growing popularity in a competitive market. In conclusion, 2472 FRP vessels are not merely an industrial product but represent a blend of scientific innovation, expert engineering, and reliable performance. Their unique properties and customization possibilities make them an invaluable asset across various sectors, promoting safety, efficiency, and sustainability in industrial applications.

Share

Latest news

-

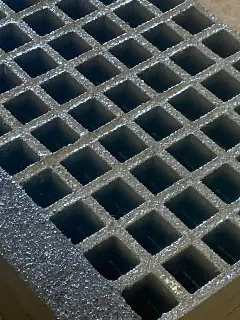

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024