loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

24 x 72 frp vessel

The Significance of 24% FRP Vessels in Modern Engineering

Fiberglass Reinforced Plastic (FRP) vessels have emerged as a significant innovation in various industries due to their unique properties and advantages over traditional materials. With the increasing demand for durable, lightweight, and corrosion-resistant storage solutions, the specification of a 24% FRP vessel designed to handle a range of applications—particularly in chemical storage—is an exciting development for engineers and manufacturers alike.

The Significance of 24% FRP Vessels in Modern Engineering

The lightweight nature of FRP vessels is also a significant advantage. Traditional storage solutions, such as steel or concrete tanks, can be cumbersome and challenging to install. In contrast, FRP vessels are considerably lighter, facilitating easier transportation and installation. This property can lead to reduced labor costs and quicker project completion times, an essential factor in industries where efficiency is key to profitability.

24 x 72 frp vessel

In terms of thermal insulation, 24% FRP vessels exhibit excellent properties, allowing them to maintain stable temperatures within. This feature is particularly beneficial when storing temperature-sensitive materials, minimizing the risks associated with temperature fluctuations and contributing to better quality control.

Moreover, the versatility in design and the ability to customize FRP vessels further solidify their status in modern engineering. Manufacturers can tailor the size, shape, and features of the vessels according to specific needs, enhancing their applicability across various sectors. Whether for large-scale industrial operations or smaller-scale applications, the adaptability of 24% FRP vessels meets diverse engineering requirements.

As the world focuses on sustainability and environmental responsibility, the use of FRP materials also aligns with these goals. With the right treatment, FRP is recyclable, and its durable design can significantly extend the life cycle of storage solutions, ultimately reducing waste and resource consumption.

In conclusion, the emergence of 24% FRP vessels represents a pivotal advancement in the realm of material science and engineering. Their combination of lightweight design, corrosion resistance, thermal insulation, and customizability positions them as an ideal choice for diverse applications, thereby promoting efficiency and sustainability within industries. As technology progresses, FRP vessels will likely continue to play a vital role in shaping the future of industrial storage solutions.

-

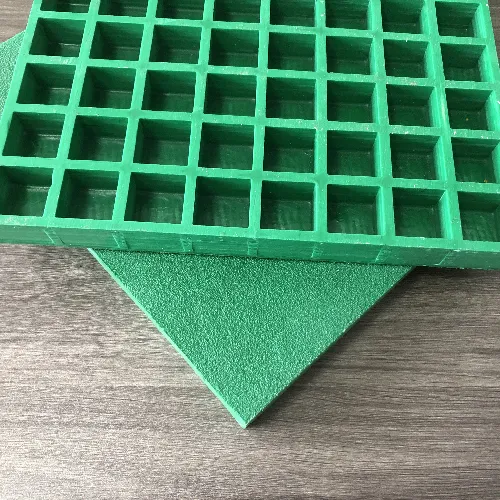

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024