loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 26, 2025 03:25

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

Discovering the Benefits and Applications of a 24 x 72 FRP Vessel

Heat and temperature fluctuations present significant challenges in industrial environments. FRP’s thermal stability allows these vessels to withstand a broad range of temperatures without compromising structural integrity, making them an excellent choice for industries where thermal conditions vary. This adaptability reinforces their application in diverse settings, ensuring that they remain unaffected by the rigorous demands of changing temperature and pressure. Moreover, the customization capabilities of FRP vessels are noteworthy. Manufacturers can tailor these vessels to meet specific industry requirements, including alterations in size, thickness, and internal fixtures. This customization flexibility ensures that each vessel fits seamlessly within its intended application, optimizing both function and space. Authoritative voice within the industry stresses the importance of choosing the right materials for containment solutions. Expert recommendations consistently point to FRP vessels as the preferred choice for applications requiring a balance of durability and affordability. Given their proven track record and widespread adoption, stakeholders can trust in the performance and reliability of FRP technology. Real-world applications continually affirm the credibility of 24 x 72 FRP vessels. From containing aggressive chemicals in chemical plants to serving as robust storage solutions in water treatment facilities, these vessels have a storied history of success. Testimonials from industry professionals highlight the improvements in operational uptime and reduction in maintenance issues after transitioning to FRP solutions, underscoring their effectiveness and dependability. In conclusion, the 24 x 72 FRP vessel is a pivotal innovation in industrial material technology. Its combination of lightweight durability, excellent corrosion resistance, and customizable design makes it a versatile solution suited for a wide array of applications. For businesses aiming to improve their operational efficiency while reducing long-term costs, investing in FRP technology offers undeniable advantages. The sustained trust and proven performance further validate its position as a leading choice for industrial containment needs.

Heat and temperature fluctuations present significant challenges in industrial environments. FRP’s thermal stability allows these vessels to withstand a broad range of temperatures without compromising structural integrity, making them an excellent choice for industries where thermal conditions vary. This adaptability reinforces their application in diverse settings, ensuring that they remain unaffected by the rigorous demands of changing temperature and pressure. Moreover, the customization capabilities of FRP vessels are noteworthy. Manufacturers can tailor these vessels to meet specific industry requirements, including alterations in size, thickness, and internal fixtures. This customization flexibility ensures that each vessel fits seamlessly within its intended application, optimizing both function and space. Authoritative voice within the industry stresses the importance of choosing the right materials for containment solutions. Expert recommendations consistently point to FRP vessels as the preferred choice for applications requiring a balance of durability and affordability. Given their proven track record and widespread adoption, stakeholders can trust in the performance and reliability of FRP technology. Real-world applications continually affirm the credibility of 24 x 72 FRP vessels. From containing aggressive chemicals in chemical plants to serving as robust storage solutions in water treatment facilities, these vessels have a storied history of success. Testimonials from industry professionals highlight the improvements in operational uptime and reduction in maintenance issues after transitioning to FRP solutions, underscoring their effectiveness and dependability. In conclusion, the 24 x 72 FRP vessel is a pivotal innovation in industrial material technology. Its combination of lightweight durability, excellent corrosion resistance, and customizable design makes it a versatile solution suited for a wide array of applications. For businesses aiming to improve their operational efficiency while reducing long-term costs, investing in FRP technology offers undeniable advantages. The sustained trust and proven performance further validate its position as a leading choice for industrial containment needs.

Share

Next:

Latest news

-

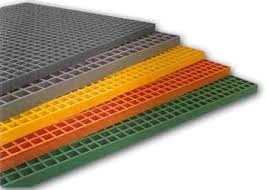

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024