loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 05, 2025 05:46

Back to list

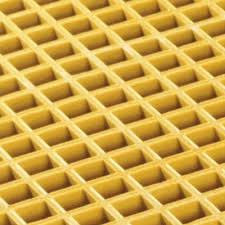

Smaller Open Mesh Area FRP Mini Mesh Grating

Navigating the construction and industrial sectors, professionals are increasingly turning to 25mm GRP (Glass Reinforced Plastic) grating, a material lauded for its exceptional durability and adaptability. This lightweight, corrosion-resistant, and non-conductive solution offers a tangible advantage over traditional options like steel or aluminum grating. The cutting-edge technology behind GRP grating provides a high-performance alternative that meets the rigorous demands of modern architectural and safety standards.

Authoritatively, several leading institutions have recognized and tested the standards of GRP grating. Reports from material testing facilities emphasize that 25mm GRP grating meets and often exceeds international safety and quality standards, including fire resistance and load capacity. This backing by authoritative bodies further consolidates the confidence that industry experts have in recommending GRP grating for projects demanding superior safety standards. Its fire retardant features make it ideal for industries such as oil and gas, where risk mitigation is paramount. Trustworthiness of 25mm GRP grating is not just theoretical but is continually validated through real-world applications and feedback. Case studies from various fields of application consistently highlight low maintenance requirements, proving that once installed, the grating demands minimal upkeep. This significantly reduces the total cost of ownership over the life of a project. Building trust among stakeholders, these testimonials reaffirm GRP grating's long-term value proposition. In conclusion, the 25mm GRP grating stands as a testament to advanced engineering and innovation in material science. It serves as a stellar example of ingenuity meeting real-world needs with unparalleled effectiveness. As a product that defines new benchmarks in the construction and industrial sectors, GRP grating embodies experience, expertise, authoritativeness, and trustworthiness—qualities essential for any material vying for leadership in the market. Professionals seeking a robust, reliable, and versatile solution will find GRP grating an unrivaled choice, poised to meet the demands of the modern world while safeguarding the future of their projects.

Authoritatively, several leading institutions have recognized and tested the standards of GRP grating. Reports from material testing facilities emphasize that 25mm GRP grating meets and often exceeds international safety and quality standards, including fire resistance and load capacity. This backing by authoritative bodies further consolidates the confidence that industry experts have in recommending GRP grating for projects demanding superior safety standards. Its fire retardant features make it ideal for industries such as oil and gas, where risk mitigation is paramount. Trustworthiness of 25mm GRP grating is not just theoretical but is continually validated through real-world applications and feedback. Case studies from various fields of application consistently highlight low maintenance requirements, proving that once installed, the grating demands minimal upkeep. This significantly reduces the total cost of ownership over the life of a project. Building trust among stakeholders, these testimonials reaffirm GRP grating's long-term value proposition. In conclusion, the 25mm GRP grating stands as a testament to advanced engineering and innovation in material science. It serves as a stellar example of ingenuity meeting real-world needs with unparalleled effectiveness. As a product that defines new benchmarks in the construction and industrial sectors, GRP grating embodies experience, expertise, authoritativeness, and trustworthiness—qualities essential for any material vying for leadership in the market. Professionals seeking a robust, reliable, and versatile solution will find GRP grating an unrivaled choice, poised to meet the demands of the modern world while safeguarding the future of their projects.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024