loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 20, 2025 13:11

Back to list

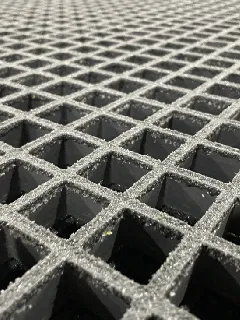

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Fiberglass grating, particularly in the dimensions of 4x8 feet, is revolutionizing many industries by offering a versatile, durable, and cost-effective alternative to traditional materials such as steel or aluminum. This article delves into the practical applications, benefits, and selection criteria for 4x8 fiberglass grating, establishing its dominance in the field with real-world experiences and expert insights.

Trustworthiness in the use of fiberglass grating also stems from its environmental advantages. Unlike metal alternatives, fiberglass does not corrode or oxidize, releasing harmful particles into the environment. Its longevity means less frequent replacement, reducing landfill waste and resource consumption. Companies prioritizing sustainability find this quality particularly appealing as it aligns with their environmental goals while also reducing costs over time. In terms of selecting the right 4x8 fiberglass grating for specific needs, having a clear understanding of the environment and application is essential. Consulting with experts who understand the nuanced properties of fiberglass can lead to custom solutions that cater precisely to load requirements, exposure conditions, and desired lifespan. For example, grit levels can be tailored for maximum traction, and color-coding can be used for safety demarcations or aesthetic appeal. In conclusion, 4x8 fiberglass grating's synthesis of adaptability, engineered strength, standard compliance, and environmental benefits makes it an authoritative choice for modern infrastructure and industrial needs. Its ability to meet rigorous demand without compromising on longevity or safety builds a trust that is unmatched, affirming its status as a hallmark of innovative material design within the industry. For businesses across sectors, investing in high-quality fiberglass grating signifies a forward-thinking approach to operational efficiency and durability.

Trustworthiness in the use of fiberglass grating also stems from its environmental advantages. Unlike metal alternatives, fiberglass does not corrode or oxidize, releasing harmful particles into the environment. Its longevity means less frequent replacement, reducing landfill waste and resource consumption. Companies prioritizing sustainability find this quality particularly appealing as it aligns with their environmental goals while also reducing costs over time. In terms of selecting the right 4x8 fiberglass grating for specific needs, having a clear understanding of the environment and application is essential. Consulting with experts who understand the nuanced properties of fiberglass can lead to custom solutions that cater precisely to load requirements, exposure conditions, and desired lifespan. For example, grit levels can be tailored for maximum traction, and color-coding can be used for safety demarcations or aesthetic appeal. In conclusion, 4x8 fiberglass grating's synthesis of adaptability, engineered strength, standard compliance, and environmental benefits makes it an authoritative choice for modern infrastructure and industrial needs. Its ability to meet rigorous demand without compromising on longevity or safety builds a trust that is unmatched, affirming its status as a hallmark of innovative material design within the industry. For businesses across sectors, investing in high-quality fiberglass grating signifies a forward-thinking approach to operational efficiency and durability.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

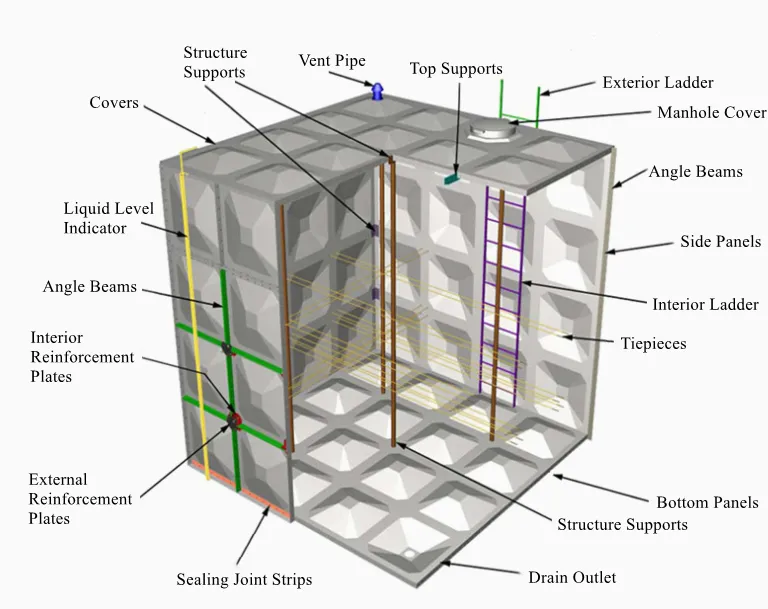

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024