loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

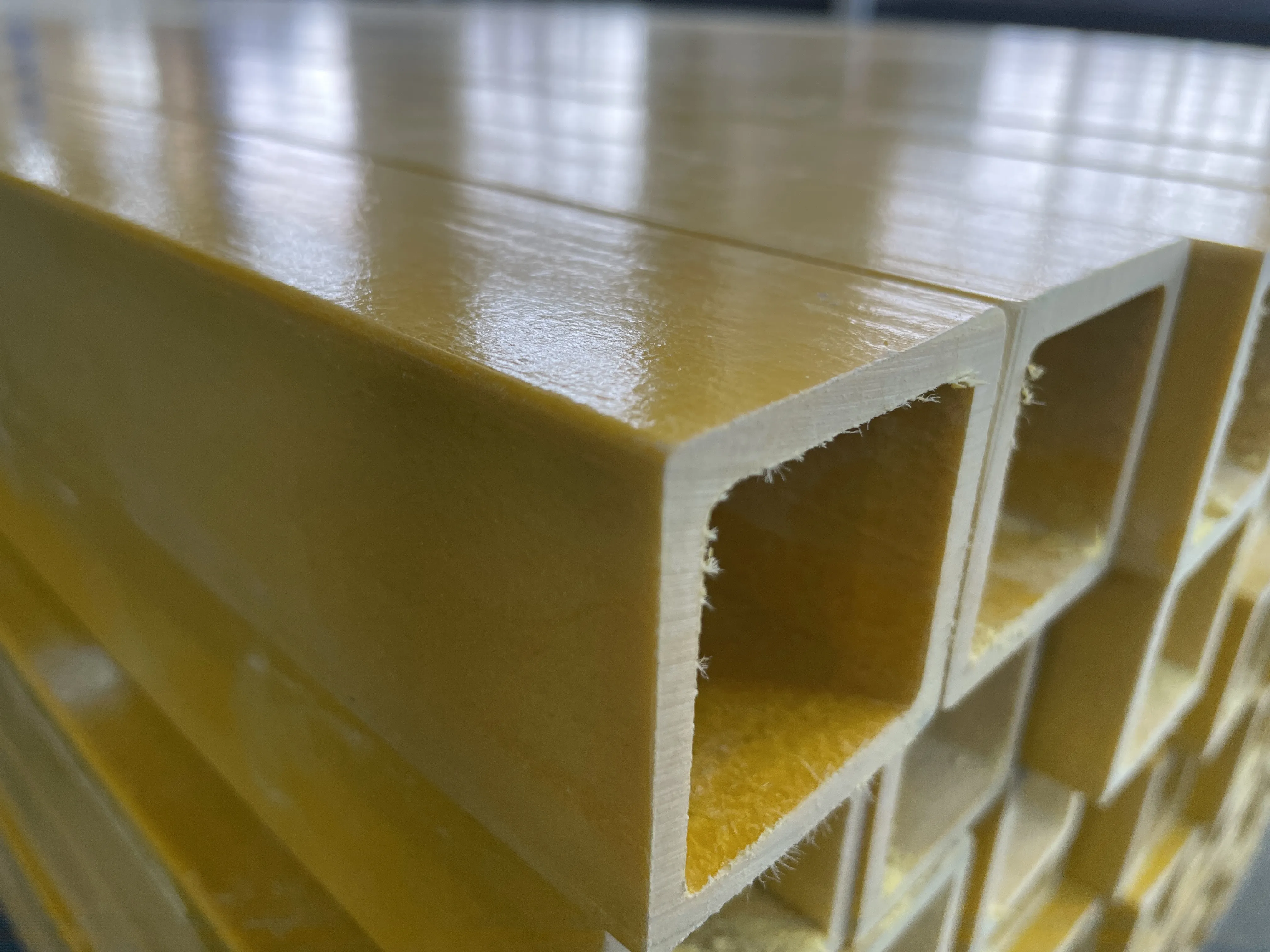

Durable 4% Open Area 8 Inch Fiberglass Grating for Various Applications

Understanding 4% 20 x 8 Fiberglass Grating Applications and Benefits

Fiberglass grating has emerged as a vital solution in various industrial and commercial applications, especially where non-metallic materials are preferred for their durability and resistance to corrosive environments. One variant that stands out in this category is the 4% 20 x 8 fiberglass grating. This specific type of grating boasts a unique combination of benefits that make it an excellent choice for a wide range of applications.

Understanding 4% 20 x 8 Fiberglass Grating Applications and Benefits

One of the most significant advantages of fiberglass grating is its exceptional resistance to harsh chemicals and environmental factors. Unlike traditional metal gratings that can corrode or rust over time, fiberglass grating remains unaffected by chemical spills, saltwater, and UV radiation. This resilience makes it an ideal choice for industries such as wastewater treatment, chemical processing, and marine applications, where exposure to corrosive elements is a daily reality.

4 x8 fiberglass grating

Additionally, the lightweight nature of fiberglass grating allows for easy installation and handling. Compared to steel or aluminum alternatives, fiberglass grating is considerably lighter, which reduces transportation costs and simplifies on-site installation. This attribute is particularly beneficial in projects where labor costs are a concern and where efficiency is paramount. Workers can install the grating quickly without the need for heavy machinery or extensive support structures.

Another essential aspect of 4% 20 x 8 fiberglass grating is its slip-resistance. Safety is a top priority in industrial environments, where spills or wet conditions can create hazardous working situations. Fiberglass grating is specifically designed with a non-slip surface that provides excellent traction, reducing the risk of slips and falls. This safety feature is crucial in maintaining a safe workplace and can help organizations avoid costly accidents and potential litigation.

Moreover, fiberglass grating requires minimal maintenance, further enhancing its appeal. Unlike metal grates that may need regular painting or treatment to prevent corrosion, fiberglass grating retains its structural integrity and aesthetic appearance without significant upkeep. This quality not only saves on maintenance costs but also contributes to a more sustainable approach by reducing the need for frequent replacements.

In conclusion, the 4% 20 x 8 fiberglass grating represents a robust and versatile solution for a variety of applications. Its combination of chemical resistance, lightweight design, slip resistance, and low maintenance requirements makes it an ideal choice for industries that demand durability and safety. Whether used in industrial plants, commercial facilities, or even municipal infrastructure, this type of grating continues to prove its worth in creating safe and efficient working environments. As industries look for reliable and sustainable materials, fiberglass grating is poised to play an increasingly prominent role in the engineering and construction landscape.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024