loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Design and Functionality of Activated Carbon Filtration Systems in Water Treatment Applications

Understanding Activated Carbon Filter Vessels

Activated carbon filter vessels play a crucial role in water and air purification processes across various industries. These specialized vessels are designed to house activated carbon, a highly porous material known for its exceptional adsorption properties. By capturing impurities, contaminants, and unwanted odors, activated carbon filter vessels enhance the overall quality of air and water, making them essential components in environmental management.

Activated carbon is produced from carbon-rich materials, such as coconut shells, wood, or coal, through a process of pyrolysis and activation. The activation process creates a vast network of pores, significantly increasing the surface area. This heightened surface area provides an ideal environment for the adsorption of molecules, allowing activated carbon to effectively trap organic compounds, chlorine, heavy metals, and volatile organic compounds (VOCs).

The design of an activated carbon filter vessel is crucial for optimizing its performance. These vessels typically consist of a sturdy outer shell, commonly made of stainless steel or fiberglass, which ensures durability and longevity. Inside, the activated carbon is arranged in a specific manner to maximize contact time with the contaminants. The flow of water or air through the vessel is carefully controlled, allowing for efficient adsorption. Depending on the application, these vessels can be designed as single-use or regenerable, where the activated carbon can be reactivated to restore its adsorption capabilities.

activated carbon filter vessel

Activated carbon filter vessels are utilized in various settings, including municipal water treatment plants, industrial processes, and residential water filtration systems. In water treatment, they effectively remove chlorine, taste, and odor, ensuring safe drinking water. In air filtration, activated carbon vessels mitigate unpleasant odors and trap harmful gases, contributing to healthier indoor environments.

Moreover, the need for activated carbon filter vessels has surged in response to growing environmental concerns and stricter regulations regarding air and water quality. Industries are increasingly adopting these systems not only to comply with legal standards but also to promote sustainability and corporate responsibility.

Despite their effectiveness, regular maintenance and timely replacement of the activated carbon are essential to ensure optimal performance. Over time, the adsorption capacity of the activated carbon diminishes, resulting in a reduced ability to trap contaminants. Thus, monitoring the system and adhering to maintenance schedules is vital for its longevity and efficiency.

In conclusion, activated carbon filter vessels are invaluable tools in the pursuit of clean air and water. Their ability to adsorb a wide range of impurities makes them versatile for different applications. As we continue to face environmental challenges, the importance of these filtration systems will only grow, making them integral to sustainable practices and public health.

-

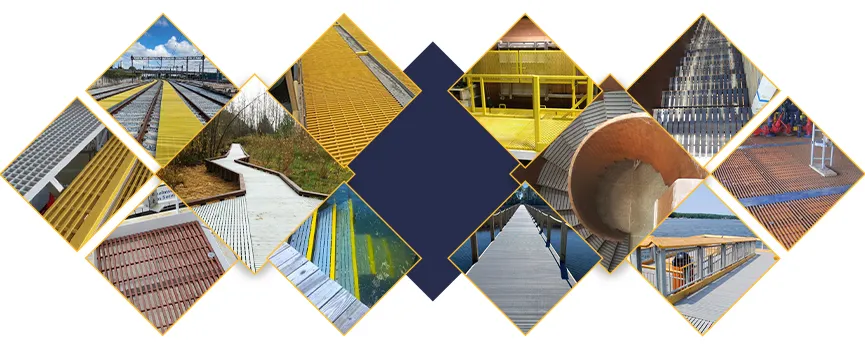

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024