loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 12, 2025 00:29

Back to list

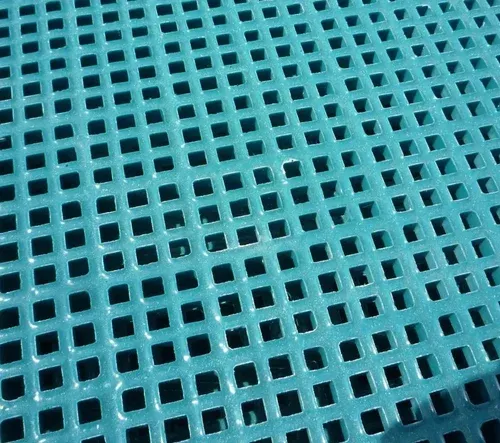

frp micro mesh grating

Choosing the right type of flooring is a significant decision for industries that deal with a lot of heavy-duty work. Aluminium floor grating emerges as an excellent choice for these environments, providing a powerful combination of strength, durability, and versatility. Renowned for its lightweight nature and resistance to corrosion, this material is becoming increasingly popular in various industrial applications. Here's a deeper dive into why aluminium floor grating is revered in the world of heavy-duty flooring solutions.

The authority of aluminium floor grating is further established by industry endorsements and compliance with international standards. Many leading organizations and governing bodies have recognized it for its reliability and structural soundness. It meets a variety of standards, such as those stipulated by the American Bureau of Shipping or the ISO regulations, which are testament to its rigorously tested quality. This authoritative backing not only underscores the credibility of the product but also builds confidence in users who prioritize safety and compliance. Trustworthiness in the context of aluminium floor grating can be attributed to its proven track record in diverse industrial applications. Companies across sectors have attested to the reliability of aluminium flooring, citing its ability to improve operational efficiency and safety. Testimonials reveal that industries that have shifted to aluminium gratings observe fewer accidents related to slipping and falling, and report better longevity and cost-efficiency compared to traditional steel gratings. This long-standing trust in aluminium floor gratings is supported by manufacturers who offer warrantees and comprehensive customer support to address any issues quickly and efficiently. In conclusion, aluminium floor grating is not just a product; it's a solution that embodies experience, expertise, authoritativeness, and trustworthiness. Its continuous innovation, compliance with industry standards, and proven effectiveness across various sectors demonstrate why it maintains an edge over other materials. For industries seeking a reliable flooring solution that promises longevity, minimal maintenance, and superior performance, aluminium floor grating stands as a formidable choice.

The authority of aluminium floor grating is further established by industry endorsements and compliance with international standards. Many leading organizations and governing bodies have recognized it for its reliability and structural soundness. It meets a variety of standards, such as those stipulated by the American Bureau of Shipping or the ISO regulations, which are testament to its rigorously tested quality. This authoritative backing not only underscores the credibility of the product but also builds confidence in users who prioritize safety and compliance. Trustworthiness in the context of aluminium floor grating can be attributed to its proven track record in diverse industrial applications. Companies across sectors have attested to the reliability of aluminium flooring, citing its ability to improve operational efficiency and safety. Testimonials reveal that industries that have shifted to aluminium gratings observe fewer accidents related to slipping and falling, and report better longevity and cost-efficiency compared to traditional steel gratings. This long-standing trust in aluminium floor gratings is supported by manufacturers who offer warrantees and comprehensive customer support to address any issues quickly and efficiently. In conclusion, aluminium floor grating is not just a product; it's a solution that embodies experience, expertise, authoritativeness, and trustworthiness. Its continuous innovation, compliance with industry standards, and proven effectiveness across various sectors demonstrate why it maintains an edge over other materials. For industries seeking a reliable flooring solution that promises longevity, minimal maintenance, and superior performance, aluminium floor grating stands as a formidable choice.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024