loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 11, 2025 19:07

Back to list

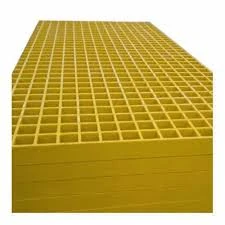

aluminum floor grating

Aluminum floor grating has emerged as a favorite among industries for its unparalleled durability, versatility, and the straightforward nature of its maintenance. It has become an indispensable product, especially in sectors requiring robust and reliable flooring solutions such as industrial factories, marine environments, and even modern architectural spaces.

From an architectural perspective, aluminum floor grating is not just a utilitarian choice but also an aesthetic one. Modern architects often incorporate this material into their designs, appreciating its sleek appearance and compatibility with contemporary styles. Given its ability to be fabricated in a variety of meshes and designs, aluminum grating offers both form and function, contributing to the structural magnificence of spaces while delivering crucial flooring support. The maintenance of aluminum floor grating is particularly commendable. Unlike other materials liable to rust, discolor, or weaken over time, aluminum requires minimal upkeep. Regular cleaning is sufficient to maintain its pristine condition – a simple wash with soap and water will typically suffice. Additionally, because it does not require the protective coatings that steel grating may need, it ensures long-term cost savings for businesses concerned about operational expenses. Despite these numerous advantages, decision-makers must still weigh various factors when selecting floor grating, considering specific load requirements, span, and environmental conditions unique to their applications. Consulting with expert suppliers, those well-versed in industrial safety standards and building codes, ensures that one gets the most suitable grating solution tailored to particular needs. In conclusion, the demand for aluminum floor grating is not just a passing trend, but a reflection of its extensive benefits across several domains. Its combination of durability, ease of installation, safety features, aesthetic flexibility, and minimal maintenance makes it a superior choice. As industries continue to pivot towards more economic and sustainable building materials, aluminum floor grating's status as a leader in flooring solutions is cemented, providing businesses with a reliable foundation upon which to operate efficiently and safely.

From an architectural perspective, aluminum floor grating is not just a utilitarian choice but also an aesthetic one. Modern architects often incorporate this material into their designs, appreciating its sleek appearance and compatibility with contemporary styles. Given its ability to be fabricated in a variety of meshes and designs, aluminum grating offers both form and function, contributing to the structural magnificence of spaces while delivering crucial flooring support. The maintenance of aluminum floor grating is particularly commendable. Unlike other materials liable to rust, discolor, or weaken over time, aluminum requires minimal upkeep. Regular cleaning is sufficient to maintain its pristine condition – a simple wash with soap and water will typically suffice. Additionally, because it does not require the protective coatings that steel grating may need, it ensures long-term cost savings for businesses concerned about operational expenses. Despite these numerous advantages, decision-makers must still weigh various factors when selecting floor grating, considering specific load requirements, span, and environmental conditions unique to their applications. Consulting with expert suppliers, those well-versed in industrial safety standards and building codes, ensures that one gets the most suitable grating solution tailored to particular needs. In conclusion, the demand for aluminum floor grating is not just a passing trend, but a reflection of its extensive benefits across several domains. Its combination of durability, ease of installation, safety features, aesthetic flexibility, and minimal maintenance makes it a superior choice. As industries continue to pivot towards more economic and sustainable building materials, aluminum floor grating's status as a leader in flooring solutions is cemented, providing businesses with a reliable foundation upon which to operate efficiently and safely.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024