loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 13, 2025 00:18

Back to list

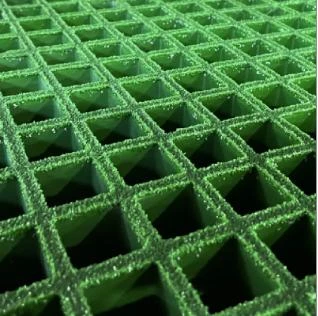

frp micro mesh grating

Anti-slip grating is a critical component in various industrial and commercial environments, where safety and efficiency are paramount. Made from materials such as steel, aluminum, or fiberglass, these grated surfaces provide a durable, reliable solution for minimizing slip hazards in areas exposed to moisture, oils, and other potentially slippery substances. The evolution of anti-slip grating technology demonstrates a commitment to innovation, addressing the demands of modern industries by combining functionality with safety.

Trust in anti-slip grating solutions is further established through rigorous testing and compliance with international safety standards. Reputable manufacturers adhere to stringent quality control processes, with their products often subject to third-party testing and certification. Such assurance of quality instills confidence in industry leaders, affirming the reliability of the gratings under various extremes. In addition to physical characteristics and capabilities, understanding the long-term economic benefits of anti-slip grating is crucial. While initial investment costs might be higher, the reduction in accident-related expenditures and insurance premiums, alongside decreased downtime from workplace incidents, underscores a substantial return on investment. Furthermore, high-quality grating requires less frequent replacement and maintenance, translating into significant cost savings over time. From a trustworthiness perspective, customer testimonials and case studies play an essential role in the decision-making process. Sharing real-world experiences and success stories from clients who have effectively implemented anti-slip solutions provides valuable insights. These narratives not only highlight the tangible benefits experienced by other businesses but also reinforce the reliability and effectiveness of the products. Informed decisions about anti-slip gratings also consider environmental impact. Eco-conscious choices, like grating manufactured from recyclable materials or processes that minimize environmental harm, align with contemporary sustainability goals. Incorporating environmentally friendly options can enhance a company's reputation and meet the growing consumer demand for green solutions. In conclusion, the selection and implementation of anti-slip grating requires careful consideration of multiple factors, underscored by experience, expertise, authoritativeness, and trustworthiness. Industry professionals must prioritize safety while balancing operational demands and cost-efficiency. By focusing on these core principles, businesses are empowered to enhance workplace environments, safeguarding employees while optimizing performance and sustainability.

Trust in anti-slip grating solutions is further established through rigorous testing and compliance with international safety standards. Reputable manufacturers adhere to stringent quality control processes, with their products often subject to third-party testing and certification. Such assurance of quality instills confidence in industry leaders, affirming the reliability of the gratings under various extremes. In addition to physical characteristics and capabilities, understanding the long-term economic benefits of anti-slip grating is crucial. While initial investment costs might be higher, the reduction in accident-related expenditures and insurance premiums, alongside decreased downtime from workplace incidents, underscores a substantial return on investment. Furthermore, high-quality grating requires less frequent replacement and maintenance, translating into significant cost savings over time. From a trustworthiness perspective, customer testimonials and case studies play an essential role in the decision-making process. Sharing real-world experiences and success stories from clients who have effectively implemented anti-slip solutions provides valuable insights. These narratives not only highlight the tangible benefits experienced by other businesses but also reinforce the reliability and effectiveness of the products. Informed decisions about anti-slip gratings also consider environmental impact. Eco-conscious choices, like grating manufactured from recyclable materials or processes that minimize environmental harm, align with contemporary sustainability goals. Incorporating environmentally friendly options can enhance a company's reputation and meet the growing consumer demand for green solutions. In conclusion, the selection and implementation of anti-slip grating requires careful consideration of multiple factors, underscored by experience, expertise, authoritativeness, and trustworthiness. Industry professionals must prioritize safety while balancing operational demands and cost-efficiency. By focusing on these core principles, businesses are empowered to enhance workplace environments, safeguarding employees while optimizing performance and sustainability.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024