loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 20, 2025 07:16

Back to list

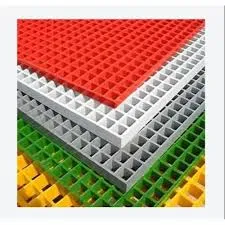

bar grating for sale

Bar grating serves as an indispensable component in numerous industrial and commercial sectors, offering robustness, durability, and safety in environments ranging from factories and warehouses to pedestrian walkways and mezzanines. If you're considering purchasing bar gratings, understanding their types, applications, and benefits will ensure you make an informed decision.

Trustworthy vendors provide comprehensive after-sales services, including installation advice, maintenance tips, and load capacity information. Partnering with these suppliers facilitates better integration of the bar grating into your infrastructure, ensuring zero compromise on both quality and safety. Furthermore, they often offer customization options to meet specific requirements, from adjusting load-bearing capacities to catering to unique layout designs. Incorporating user feedback is also essential to cultivating a product's trustworthiness. Real-world applications and client success stories reflect the grating's performance and reliability, assuring potential buyers of its efficacy. Testimonials from industries such as aerospace, manufacturing, and infrastructure development reveal a consistent pattern of satisfaction, often highlighting significant improvements in operational safety and efficiency. For businesses seeking bar grating solutions, conducting a meticulous online search using keyword-focused strategies—such as bar grating for sale—can critically enhance visibility. By examining detailed manufacturer profiles, industry certifications, and customer reviews, one gains a holistic understanding of product offerings. In conclusion, sourcing bar grating requires careful attention to quality, application needs, and supplier credibility. By prioritizing these factors, you assure the safety and operational success of your projects while maximizing return on investment. Whether it's ensuring pedestrian safety with non-slip surfaces or supporting heavy industrial activities, the right bar grating product is an invaluable asset to any enterprise.

Trustworthy vendors provide comprehensive after-sales services, including installation advice, maintenance tips, and load capacity information. Partnering with these suppliers facilitates better integration of the bar grating into your infrastructure, ensuring zero compromise on both quality and safety. Furthermore, they often offer customization options to meet specific requirements, from adjusting load-bearing capacities to catering to unique layout designs. Incorporating user feedback is also essential to cultivating a product's trustworthiness. Real-world applications and client success stories reflect the grating's performance and reliability, assuring potential buyers of its efficacy. Testimonials from industries such as aerospace, manufacturing, and infrastructure development reveal a consistent pattern of satisfaction, often highlighting significant improvements in operational safety and efficiency. For businesses seeking bar grating solutions, conducting a meticulous online search using keyword-focused strategies—such as bar grating for sale—can critically enhance visibility. By examining detailed manufacturer profiles, industry certifications, and customer reviews, one gains a holistic understanding of product offerings. In conclusion, sourcing bar grating requires careful attention to quality, application needs, and supplier credibility. By prioritizing these factors, you assure the safety and operational success of your projects while maximizing return on investment. Whether it's ensuring pedestrian safety with non-slip surfaces or supporting heavy industrial activities, the right bar grating product is an invaluable asset to any enterprise.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024