loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

3 月 . 07, 2025 01:17

Back to list

bar grating for sale

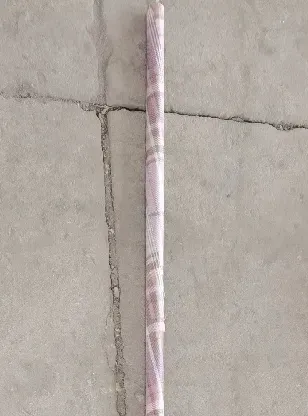

Finding the right bar grating can be a daunting task for both seasoned industry professionals and newcomers alike. With the rising demand for durable and reliable materials in construction and industrial projects, bar grating has emerged as a versatile solution. Whether you are looking to improve facility safety or enhance design aesthetics, understanding the nuances of bar grating can significantly impact your purchase decision.

An often-overlooked aspect is the environmental consideration. With growing emphasis on sustainable building materials, many manufacturers are offering bar grating options that incorporate recycled materials, aiding companies in achieving their sustainability goals. Always inquire about the recyclability and environmental impact of the bar grating you're considering. To navigate the complexities of purchasing bar grating, partnering with a reputable supplier is crucial. Established suppliers offer not only a wide range of options but also provide expert guidance on selecting the right type and size of grating for your specific needs. A knowledgeable supplier can offer insights into industry standards and regulatory compliance, ensuring that your project meets all necessary safety and quality standards. When making a purchase decision, it’s also advisable to seek out customer testimonials and case studies from previous projects. This real-world feedback can provide valuable insights into the performance and reliability of the grating over time and under different conditions. In summary, bar grating is a foundational element in many industrial and commercial applications, offering solutions that balance durability, safety, and aesthetic appeal. By considering the material composition, surface finish, load requirements, and supplier reputation, you can make an informed decision that meets the demands of your project. With the right choice, bar grating can offer a resilient, cost-effective solution for years to come, securing not just your premises but also your peace of mind.

An often-overlooked aspect is the environmental consideration. With growing emphasis on sustainable building materials, many manufacturers are offering bar grating options that incorporate recycled materials, aiding companies in achieving their sustainability goals. Always inquire about the recyclability and environmental impact of the bar grating you're considering. To navigate the complexities of purchasing bar grating, partnering with a reputable supplier is crucial. Established suppliers offer not only a wide range of options but also provide expert guidance on selecting the right type and size of grating for your specific needs. A knowledgeable supplier can offer insights into industry standards and regulatory compliance, ensuring that your project meets all necessary safety and quality standards. When making a purchase decision, it’s also advisable to seek out customer testimonials and case studies from previous projects. This real-world feedback can provide valuable insights into the performance and reliability of the grating over time and under different conditions. In summary, bar grating is a foundational element in many industrial and commercial applications, offering solutions that balance durability, safety, and aesthetic appeal. By considering the material composition, surface finish, load requirements, and supplier reputation, you can make an informed decision that meets the demands of your project. With the right choice, bar grating can offer a resilient, cost-effective solution for years to come, securing not just your premises but also your peace of mind.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024