loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 23, 2025 05:22

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

Experience, expertise, authoritativeness, and trustworthiness are paramount when discussing cartridge filter vessels, a critical component for industries relying on filtration systems to ensure operational efficiency. As a seasoned professional in the filtration industry, I bring firsthand insights into the intricate dynamics of cartridge filter vessels, tailored for those seeking reliable, efficient, and scalable filtration solutions.

In an era where every industrial process is closely scrutinized for compliance, the authoritativeness of cartridge filter vessels rests on adherence to regulatory standards. Vessels must conform to industry standards such as ASME, ensuring they meet the rigorous quality and safety benchmarks. This not only affirms their credibility but also upholds the reputation of businesses leveraging these systems for critical operations. Trustworthiness of cartridge filter vessels is further underscored by the track record of manufacturers and suppliers. A reliable supply chain partner is pivotal. They not only provide superior products but also expert installation, technical support, and after-sales service. This engenders trust, as industries can depend on these partners for consistent performance and immediate assistance during unforeseen disruptions. In conclusion, the choice of a cartridge filter vessel is far-reaching in its impact on operational efficacy and sustainability. It necessitates an informed, nuanced approach balancing material selection, compliance, and supplier reliability. Understanding these elements from an experienced, expert-led perspective enables industries to make informed decisions that drive efficiency while mitigating risks associated with faulty filtration systems. For those embarking on or refining their filtration strategy, a thorough assessment of cartridge filter vessels, backed by authoritative insights and trustworthy partnerships, is fundamental for achieving optimal outcomes in both product quality and operational excellence.

In an era where every industrial process is closely scrutinized for compliance, the authoritativeness of cartridge filter vessels rests on adherence to regulatory standards. Vessels must conform to industry standards such as ASME, ensuring they meet the rigorous quality and safety benchmarks. This not only affirms their credibility but also upholds the reputation of businesses leveraging these systems for critical operations. Trustworthiness of cartridge filter vessels is further underscored by the track record of manufacturers and suppliers. A reliable supply chain partner is pivotal. They not only provide superior products but also expert installation, technical support, and after-sales service. This engenders trust, as industries can depend on these partners for consistent performance and immediate assistance during unforeseen disruptions. In conclusion, the choice of a cartridge filter vessel is far-reaching in its impact on operational efficacy and sustainability. It necessitates an informed, nuanced approach balancing material selection, compliance, and supplier reliability. Understanding these elements from an experienced, expert-led perspective enables industries to make informed decisions that drive efficiency while mitigating risks associated with faulty filtration systems. For those embarking on or refining their filtration strategy, a thorough assessment of cartridge filter vessels, backed by authoritative insights and trustworthy partnerships, is fundamental for achieving optimal outcomes in both product quality and operational excellence.

Share

Latest news

-

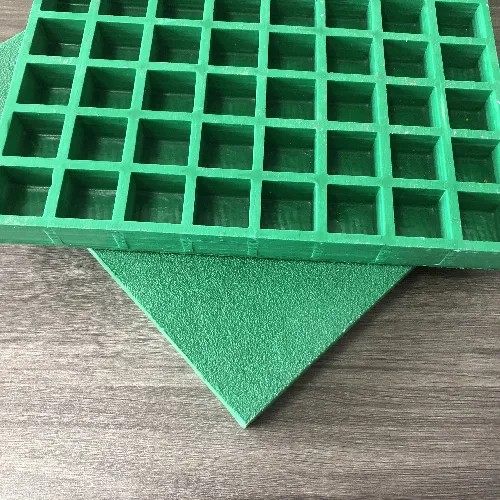

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

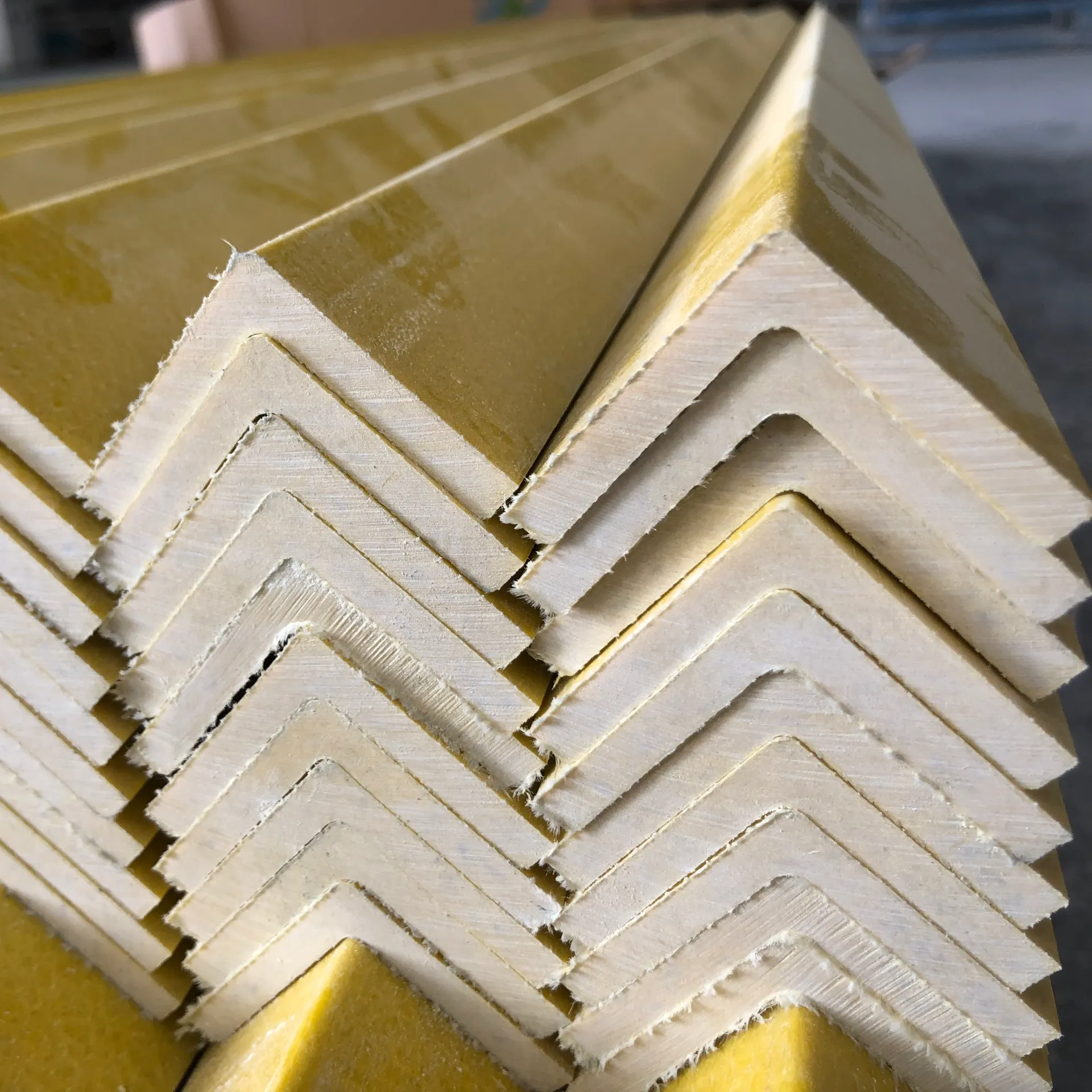

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024