loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

chs pipe

Understanding CHS Pipe A Comprehensive Overview

CHS pipe, or Circular Hollow Section pipe, has become increasingly popular in various construction and structural applications worldwide. Its unique shape and properties make it an essential choice for many engineers and architects, providing both aesthetic appeal and functional durability.

What is CHS Pipe?

As the name suggests, CHS pipe is characterized by its circular cross-section, which distinguishes it from other hollow sections, such as rectangular or square hollow sections (RHS and SHS). Typically manufactured from carbon steel, stainless steel, or other alloys, CHS pipes are produced through hot or cold forming processes that ensure uniformity and strength.

The sizes of CHS pipes can vary significantly, depending on their intended application. Standard dimensions are available, but custom sizes can also be fabricated according to project specifications. The structural integrity of CHS pipe, coupled with its lightweight nature, makes it an ideal choice for a multitude of uses ranging from building frames and bridges to scaffolding and pipelines.

Advantages of CHS Pipe

1. Strength-to-Weight Ratio One of the most notable advantages of CHS pipe is its excellent strength-to-weight ratio. This means that engineers can construct robust frameworks without adding unnecessary weight, making it energy-efficient and cost-effective in transportation and installation.

2. Versatility CHS pipes exhibit versatility in various applications. They are suitable for structural, mechanical, and fluid transport usage. This versatility is essential in industries such as construction, engineering, and manufacturing, where different applications demand different solution characteristics.

chs pipe

3. Aesthetic Appeal The round shape of CHS pipes lends itself to more architecturally pleasing designs. It allows for the creation of curved and flowing lines in construction, contributing to modern architectural aesthetics.

4. Resistance to Stress Concentration The circular shape helps in evenly distributing stresses across the surface. Unlike corners found in rectangular or square sections, which tend to be weaker points, the absence of corners in CHS pipe minimizes stress concentration, enhancing its overall structural performance.

5. Ease of Connection Various connection techniques can be utilized with CHS pipe, making it easy to join with other materials. Welding, bolting, and structural adhesives can be employed to ensure secure and durable connections.

Applications of CHS Pipe

The applications for CHS pipe are extensive and varied. They are frequently used in

- Construction As a primary structural element in building frames, CHS pipes provide strength while allowing for open spaces and varied design elements. - Infrastructure Many bridges use CHS pipes for supporting structures, ensuring long-lasting durability in harsh environments. - Scaffolding The lightweight yet strong nature of CHS pipes makes them an excellent choice for temporary structures that facilitate construction efforts. - Pipelines In both water and gas distribution, CHS pipes are used due to their ability to carry fluids efficiently while resisting corrosion when coated properly.

Conclusion

In summary, CHS pipe stands out as a versatile, strong, and aesthetically pleasing solution for a variety of applications. Its unique properties and advantages position it as a preferred choice in modern construction and engineering. As technology continues to advance, the manufacturing processes and applications of CHS pipes are likely to expand further, ensuring their relevance in future projects. Whether for structural integrity or design aesthetics, CHS pipes will remain a vital component in the development of contemporary infrastructure.

-

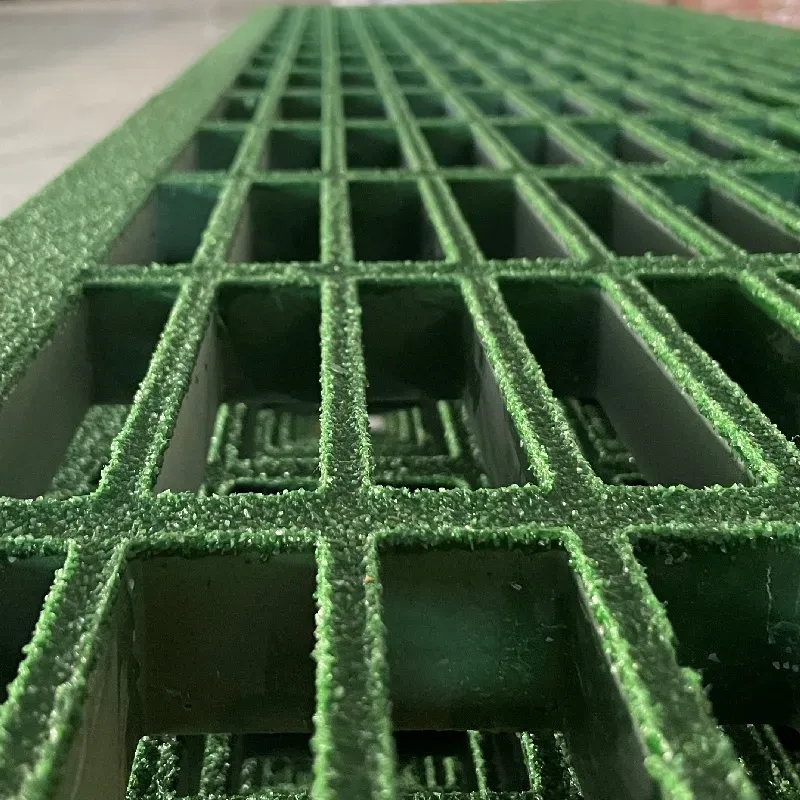

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024