loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 04, 2025 03:37

Back to list

large square water tanks

Understanding CHS pipe sizes is crucial for professionals in industries such as construction, plumbing, and engineering. Circular Hollow Sections (CHS) are a versatile and robust solution for various applications. Their geometric design offers uniform strength distribution and aesthetic appeal, making them a preferred choice for architects and engineers. This article delves into CHS pipe sizes, exploring their specifications, benefits, and applications, and providing the expertise needed to make informed choices in projects requiring these materials.

Precision in material selection, design alignment, and size compatibility are paramount to optimizing the benefits of CHS pipes. Engineers must use comprehensive calculations and testing to ensure that selected pipe sizes and specifications align with project demands, thereby safeguarding structural integrity and functionality. Projects utilizing CHS pipes frequently involve collaboration between various professionals, including architects, engineers, and fabricators. Each stakeholder contributes critical insights to ensure that the chosen pipe sizes and materials meet the design needs and safety standards. This collaborative approach not only reinforces the technical soundness of the project but also builds trust among clients and stakeholders, emphasizing the reliability and authority of the professionals involved. CHS pipes are utilized in a myriad of applications, ranging from residential buildings and commercial constructions to infrastructure and industrial projects. Their ability to support large spans without intermediate supports makes them ideal for use in bridges, roof trusses, and pylons. Additionally, their inherent stability and compatibility with other materials make them suitable for retrofitting and reinforcing existing structures. To summarize, a thorough comprehension of CHS pipe sizes and their applications can significantly impact the successful completion of a project. By understanding the importance of dimensions, material selection, and design integration, professionals can make expert decisions that enhance the structural integrity, aesthetic appeal, and longevity of their constructions. Trust in CHS pipe solutions continues to grow as engineers and architects increasingly recognize their unique benefits and versatility, reinforcing their authority in the field of modern construction materials.

Precision in material selection, design alignment, and size compatibility are paramount to optimizing the benefits of CHS pipes. Engineers must use comprehensive calculations and testing to ensure that selected pipe sizes and specifications align with project demands, thereby safeguarding structural integrity and functionality. Projects utilizing CHS pipes frequently involve collaboration between various professionals, including architects, engineers, and fabricators. Each stakeholder contributes critical insights to ensure that the chosen pipe sizes and materials meet the design needs and safety standards. This collaborative approach not only reinforces the technical soundness of the project but also builds trust among clients and stakeholders, emphasizing the reliability and authority of the professionals involved. CHS pipes are utilized in a myriad of applications, ranging from residential buildings and commercial constructions to infrastructure and industrial projects. Their ability to support large spans without intermediate supports makes them ideal for use in bridges, roof trusses, and pylons. Additionally, their inherent stability and compatibility with other materials make them suitable for retrofitting and reinforcing existing structures. To summarize, a thorough comprehension of CHS pipe sizes and their applications can significantly impact the successful completion of a project. By understanding the importance of dimensions, material selection, and design integration, professionals can make expert decisions that enhance the structural integrity, aesthetic appeal, and longevity of their constructions. Trust in CHS pipe solutions continues to grow as engineers and architects increasingly recognize their unique benefits and versatility, reinforcing their authority in the field of modern construction materials.

Share

Next:

Latest news

-

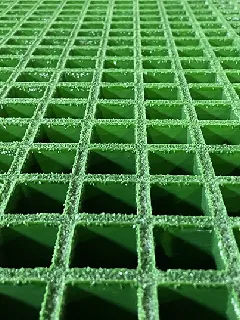

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024