loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

chs tube

Exploring CHS Tube A Versatile Solution for Modern Applications

In the realm of modern engineering and manufacturing, the CHS (Circular Hollow Section) tube has emerged as a fundamental component in a variety of applications. Characterized by its unique circular shape, the CHS tube provides a blend of strength, versatility, and functionality, making it a preferred choice for architects, engineers, and builders alike.

.

Another notable feature of the CHS tube is its aesthetic appeal. The sleek and modern look of a circular tube can enhance the overall design of a structure, making it suitable for both industrial and architectural purposes. Whether used as part of a contemporary building facade or as decorative elements in furniture design, CHS tubes add a touch of sophistication. Their smooth surface also allows for various finishing options, enabling customization to meet specific design requirements.

chs tube

In addition to their strength and aesthetic qualities, CHS tubes are highly versatile. They can be manufactured in various sizes and thicknesses, catering to diverse applications ranging from light-duty structures to heavy-duty installations. The ability to easily connect CHS tubes with other materials, such as steel plates or welding components, further enhances their usability. This adaptability has led to their widespread use in multiple industries, including construction, automotive, and manufacturing.

One of the emerging trends in the use of CHS tubes is their application in sustainable design. As industries increasingly seek to minimize their environmental impact, the demand for materials that offer both durability and recyclability has surged. CHS tubes, often made from steel or aluminum, can be recycled at the end of their life cycle, making them an eco-friendly choice. Their strength and longevity also reduce the need for frequent replacements, contributing to overall sustainability.

Furthermore, the manufacturing processes used to create CHS tubes have evolved significantly. Advances in technology have led to improved production methods that ensure better quality control and more efficient use of resources. Techniques such as cold forming, hot rolling, and laser cutting allow for precise specifications and reduced waste, aligning with modern manufacturing standards.

In conclusion, the CHS tube stands as a testament to the evolution of engineering materials. Its combination of strength, versatility, aesthetic appeal, and sustainable characteristics makes it an ideal choice for a plethora of applications. As industries continue to innovate and focus on sustainability, the use of CHS tubes is likely to expand, paving the way for creative solutions in design and construction. Whether in bold architectural feats or functional industrial designs, the ubiquitous influence of the CHS tube is undeniable, marking a significant chapter in the story of modern materials engineering.

-

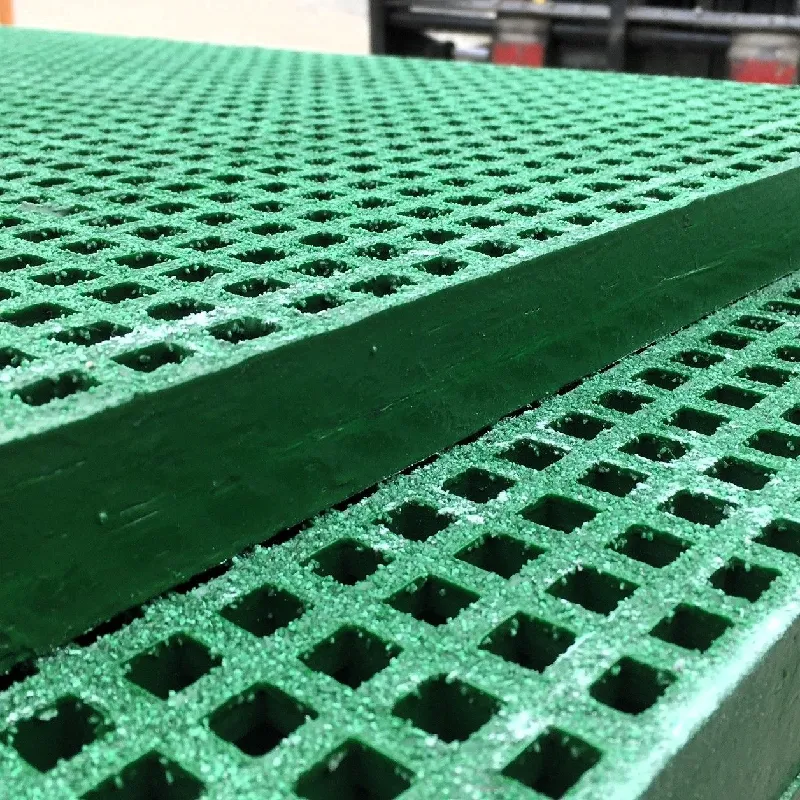

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024