loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Understanding CHS Tube Sizes for Construction and Engineering Applications

Understanding CHS Tube Sizes A Comprehensive Guide

Cold-formed hollow sections (CHS) are a popular choice in construction and structural engineering due to their strength, versatility, and ease of fabrication. These tubes, made from cold-rolled steel, are known for their circular cross-sections and are widely used in various applications including buildings, bridges, and infrastructure projects. Choosing the right CHS tube size is crucial for ensuring that a structure can support the required loads while remaining efficient and cost-effective.

Understanding CHS Tube Sizes A Comprehensive Guide

CHS tubes come in various sizes, usually categorized by their outer diameter and wall thickness. Common CHS sizes range from smaller diameters, such as 20mm OD, to larger sizes exceeding 500mm OD. The wall thickness can range from 1.6mm to as much as 20mm, depending on the load-bearing needs. It is essential to consult the relevant standards and guidelines, such as those published by the American Institute of Steel Construction (AISC) or the British Standards Institution (BSI), to determine the appropriate specifications for each project.

chs tube sizes

The selection of CHS tube sizes also involves considering factors such as the type of load (tension, compression, bending), environmental conditions, and connections to other structural elements. For instance, larger tubes may be needed in areas subjected to higher stress, while smaller tubes could suffice for lighter loads. Additionally, it’s important to consider how the CHS tubes will be joined to other materials, as this can affect the overall performance of the structure.

Another critical consideration is the availability of CHS tubes in different grades of steel, each possessing distinct mechanical properties. Higher-grade steel can offer enhanced strength and durability, making it suitable for demanding applications.

In conclusion, selecting the appropriate CHS tube size is an essential step in the design and construction process. Engineers and architects must take into account the specific requirements of their projects, including load conditions and material properties, to ensure structural integrity and efficiency. With the wide range of available sizes and specifications, CHS tubes remain a vital component in the realm of modern construction.

-

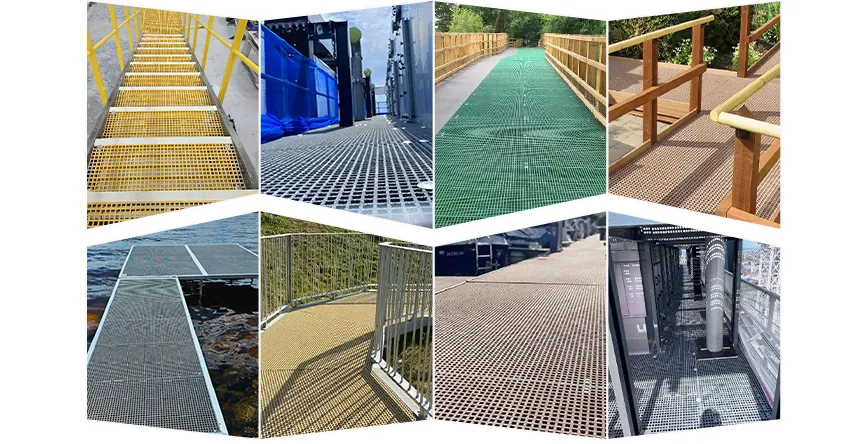

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024