loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring CHS Tube Dimensions and Their Applications in Engineering and Construction

Understanding CHS Tube Sizes A Comprehensive Guide

Cold-formed hollow sections (CHS), also known as cold-formed steel sections, are widely used in construction and engineering due to their structural efficiency and versatility. Understanding the sizing of these tubes is crucial for engineers, architects, and builders alike, as it directly affects the structural integrity and overall performance of constructions.

What is CHS?

CHS is a type of steel beam characterized by its hollow circular cross-section. The manufacturing process involves cold-forming steel into a desired shape, which enhances its strength and durability. The tube shapes can be circular, square, or rectangular, although circular hollow sections are most commonly referred to as CHS.

Importance of Size in CHS

The size of CHS tubes plays a vital role in determining their application. Sizes are generally specified in terms of external diameter, wall thickness, and length. The dimensions impact not only the strength and stability of structures but also their weight, which is crucial for transportation and installation.

Standard Sizes

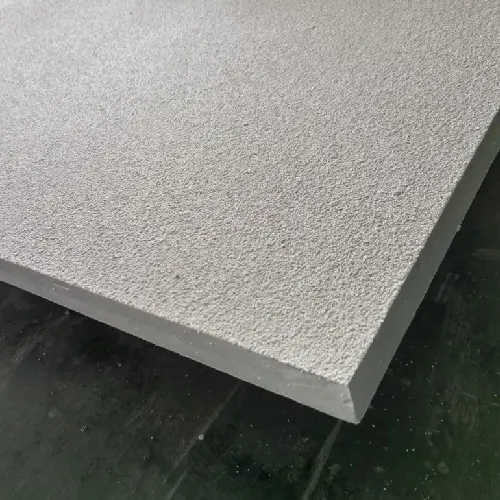

chs tube sizes

CHS tubes are typically available in various standard sizes, indicated by their outer diameter (OD) and wall thickness. Common outer diameters range from 20 mm to 600 mm, while wall thicknesses can vary from 1.5 mm to 20 mm and beyond. This standardization allows for easier design and construction, as manufacturers and builders can readily specify and source the required sizes.

Selection Criteria

When selecting the appropriate size of CHS for a project, several factors must be taken into consideration 1. Load Requirements The anticipated loads, including dead loads (permanent/static loads) and live loads (temporary/dynamic loads), dictate the required strength of the CHS. 2. Material Properties Different grades of steel exhibit varying strengths and ductility, impacting how thin or thick the walls of the tube should be. 3. Environmental Conditions Corrosion resistance, especially in outdoor or industrial applications, may necessitate specific coatings or material types that influence the choice of CHS sizes. 4. Aesthetic Factors In architectural applications, the visual impact of CHS can be as significant as its structural capabilities. The size and shape can influence the overall aesthetics of a building.

Conclusion

Understanding CHS tube sizes is imperative in the fields of construction and structural engineering. The correct selection of size not only ensures the safety and integrity of the structure but also aids in optimizing material usage, cost efficiency, and sustainability. By adhering to standard sizing and taking into account the critical factors influencing selection, professionals can effectively leverage the advantages of CHS in their designs.

In summary, CHS tubes represent a fundamental component within modern engineering solutions. Their diverse sizes and shapes offer unmatched flexibility for a variety of applications, making them indispensable in both aesthetic and structural designs. As technology advances and new standards emerge, an ongoing commitment to understanding CHS specifications will remain essential for industry professionals.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024