loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 12, 2025 16:54

Back to list

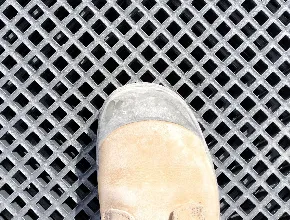

Corrosion Resistant and Slip Resistant FRP GRP Fiberglass Covered Grating

Covered gratings represent an innovative solution in industrial and architectural design, effectively combining safety, durability, and aesthetics. These structures are essentially panels made of metal, fiberglass, or other materials designed to cover large areas to prevent debris accumulation while allowing light and fluids to pass through. This inherent utility positions covered gratings as an essential component across various industries, from construction to manufacturing.

Architects and designers appreciate covered gratings for their versatility and aesthetic potential. With customization options available in patterns and finishes, these gratings can complement modern architectural designs, adding a sleek and industrial flair to various structures. Their ability to blend function with form underscores their authoritative presence in architectural planning, ensuring they meet both creative and regulatory requirements. Trustworthiness is a pivotal consideration for any product designed to bear weight and withstand environmental pressures. Covered gratings that comply with international safety standards such as ISO and ASTM offer users confidence in their performance and safety. Moreover, manufacturers that provide detailed load-bearing specifications and user guidelines further enhance this trust. By fostering transparent communication and providing extensive support, these manufacturers build enduring relationships with clients who prioritize safety and reliability. Considering sustainability trends, eco-friendly materials in covered gratings are gaining traction. Aluminum and recycled plastics are increasingly popular for their reduced environmental impact. Opting for these materials not only supports sustainable practices but also appeals to eco-conscious consumers who value responsibility alongside performance. In conclusion, covered gratings embody a product category where experience, expertise, authoritativeness, and trustworthiness converge. Their diverse applications across multiple sectors highlight their indispensable role in ensuring safety and efficiency. By leveraging advanced materials and manufacturing processes, covered gratings consistently meet the high standards demanded by modern industry and architecture. Embracing this synergy ensures they remain an integral component in any infrastructure or design plan, meeting both practical requirements and aesthetic aspirations.

Architects and designers appreciate covered gratings for their versatility and aesthetic potential. With customization options available in patterns and finishes, these gratings can complement modern architectural designs, adding a sleek and industrial flair to various structures. Their ability to blend function with form underscores their authoritative presence in architectural planning, ensuring they meet both creative and regulatory requirements. Trustworthiness is a pivotal consideration for any product designed to bear weight and withstand environmental pressures. Covered gratings that comply with international safety standards such as ISO and ASTM offer users confidence in their performance and safety. Moreover, manufacturers that provide detailed load-bearing specifications and user guidelines further enhance this trust. By fostering transparent communication and providing extensive support, these manufacturers build enduring relationships with clients who prioritize safety and reliability. Considering sustainability trends, eco-friendly materials in covered gratings are gaining traction. Aluminum and recycled plastics are increasingly popular for their reduced environmental impact. Opting for these materials not only supports sustainable practices but also appeals to eco-conscious consumers who value responsibility alongside performance. In conclusion, covered gratings embody a product category where experience, expertise, authoritativeness, and trustworthiness converge. Their diverse applications across multiple sectors highlight their indispensable role in ensuring safety and efficiency. By leveraging advanced materials and manufacturing processes, covered gratings consistently meet the high standards demanded by modern industry and architecture. Embracing this synergy ensures they remain an integral component in any infrastructure or design plan, meeting both practical requirements and aesthetic aspirations.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024