loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Understanding the Benefits and Applications of Fiberglass Bar Grating in Construction

Understanding Fiberglass Bar Grating Applications, Benefits, and Features

Fiberglass bar grating is a versatile and innovative product used across various industries for flooring, walkways, platforms, and other structural applications. Made from a combination of fiberglass reinforced plastic (FRP) and resin, this type of grating offers a unique solution that combines strength, durability, and lightweight characteristics, making it a preferred choice in environments where traditional materials may fail.

Composition and Manufacturing Process

Fiberglass bar grating is created through a pultrusion process, which involves pulling fiberglass reinforcement through a resin bath and then through a heated die. This method ensures a continuous, uniform product with consistent dimensions and high-quality performance. The end result is a grid-like structure comprising individual fiberglass bars that are arranged side by side with spaces between them, allowing for drainage while providing necessary support.

Advantages of Fiberglass Bar Grating

1. Corrosion Resistance One of the primary benefits of fiberglass grating is its exceptional resistance to corrosion. Unlike metal grating, which can rust and degrade over time when exposed to moister environments or harsh chemicals, fiberglass does not corrode. This characteristic makes it ideal for use in chemical processing plants, wastewater treatment facilities, and marine applications.

2. Lightweight and Easy to Install Fiberglass bar grating is significantly lighter than its steel or aluminum counterparts, making it easier to handle and install. Its lightweight nature reduces labor costs and allows for less intensive structural support requirements, which can save on construction materials and costs.

3. Customization Fiberglass grating can be manufactured to meet specific design requirements. It is available in various sizes, colors, and load ratings, offering flexibility for designers and engineers. Customization capabilities include different bar spacing, thicknesses, and chemical or UV-resistant finishes.

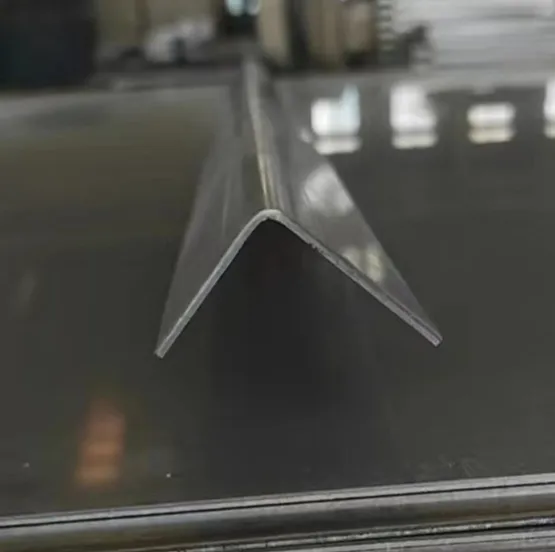

fiberglass bar grating

4. Anti-Slip Properties Safety is a crucial consideration in industrial settings, and fiberglass bar grating often comes with anti-slip surface options. This feature helps to reduce the risk of slips and falls, particularly in wet or oily environments, making it a safer choice for walkways and platforms.

5. Thermal and Electrical Insulation Being non-conductive, fiberglass grating is an excellent option for areas where electrical insulations are required, such as in electrical substations or near high-voltage equipment. Additionally, it does not get as hot or cold as metal grating, making it more comfortable for bare feet in outdoor settings.

Applications of Fiberglass Bar Grating

Fiberglass bar grating is used across a wide range of industries. Here are a few common applications

- Chemical Processing Used for walkways, platforms, and trench covers due to its resistance to harsh chemicals. - Water and Wastewater Treatment Ideal for grates, platforms, and equipment supports where water exposure is constant. - Marine and Boating Its non-corrosive properties make it perfect for docks, piers, and boat ramps. - Food Processing The ease of cleaning and resistance to chemicals make fiberglass grating a suitable choice for food processing areas. - Mining and Heavy Industry Provides long-lasting support in harsh environments, including around machinery and conveyor systems.

Conclusion

In conclusion, fiberglass bar grating represents an advanced solution equipped to meet the demands of modern industrial applications. With its unique blend of strength, safety, and resistance to corrosive environments, it stands out as an essential material in many sectors. By choosing fiberglass bar grating, industries can improve safety, reduce maintenance costs, and extend the life of their infrastructure. Thus, recognizing the benefits and suitable applications of this innovative material is crucial for anyone involved in construction, engineering, or facility management. As industries continue to evolve, the use of fiberglass bar grating is likely to expand, providing further enhancements in efficiency and safety.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024