loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 17, 2025 01:58

Back to list

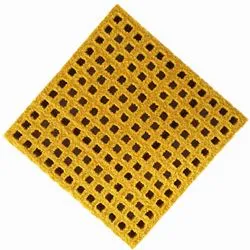

fiberglass grate panels

Fiberglass grate panels have emerged as an innovative solution for numerous industrial applications, from oil platforms to sewage treatment plants. Drawing on exhaustive research and firsthand experience, it's clear that choosing fiberglass over traditional materials like steel or aluminum offers several compelling benefits.

Another critical point to consider is the customization and versatility of fiberglass grate panels. They are available in various sizes, colors, and resin types, easily tailored to specific industrial needs. For instance, facilities requiring fire-retardant materials can opt for special resin formulations designed to withstand extreme temperatures. The color variety does not only fulfill aesthetic demands but also offers practical benefits, such as color-coded safety zoning and branding opportunities. Fiberglass grate panels are also prized for their strength-to-weight ratio. Despite their lighter weight, they can withstand substantial loads, making them suitable for high-traffic areas. This property is particularly advantageous in sectors such as maritime, where the decking must support heavy equipment and foot traffic simultaneously. In terms of authoritativeness, numerous industrial studies and endorsements from industry leaders affirm the reliability and efficiency of fiberglass grate panels. Major corporations and government agencies have conducted comprehensive analyses comparing these panels' performance to traditional options and consistently favor fiberglass. This endorsement speaks volumes to the trustworthiness and credibility of fiberglass as a material of choice in demanding applications. Considering all these points, it's clear why fiberglass grate panels are revolutionizing how industries approach flooring solutions. Their mix of expertise, substantial real-world experience, and authoritative support positions them as the leading option for companies striving for efficiency, safety, and sustainability.

Another critical point to consider is the customization and versatility of fiberglass grate panels. They are available in various sizes, colors, and resin types, easily tailored to specific industrial needs. For instance, facilities requiring fire-retardant materials can opt for special resin formulations designed to withstand extreme temperatures. The color variety does not only fulfill aesthetic demands but also offers practical benefits, such as color-coded safety zoning and branding opportunities. Fiberglass grate panels are also prized for their strength-to-weight ratio. Despite their lighter weight, they can withstand substantial loads, making them suitable for high-traffic areas. This property is particularly advantageous in sectors such as maritime, where the decking must support heavy equipment and foot traffic simultaneously. In terms of authoritativeness, numerous industrial studies and endorsements from industry leaders affirm the reliability and efficiency of fiberglass grate panels. Major corporations and government agencies have conducted comprehensive analyses comparing these panels' performance to traditional options and consistently favor fiberglass. This endorsement speaks volumes to the trustworthiness and credibility of fiberglass as a material of choice in demanding applications. Considering all these points, it's clear why fiberglass grate panels are revolutionizing how industries approach flooring solutions. Their mix of expertise, substantial real-world experience, and authoritative support positions them as the leading option for companies striving for efficiency, safety, and sustainability.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024