loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

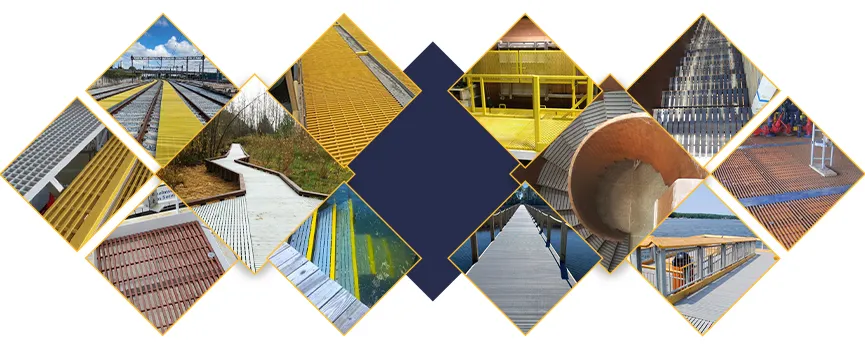

fiberglass grating

Understanding Fiberglass Grating Advantages and Applications

Fiberglass grating, a composite material composed of glass fibers and a resin binder, has steadily gained popularity in various industrial and commercial applications. Its unique properties make it an ideal solution for environments where traditional materials like steel or wood may fall short. This article explores the advantages of fiberglass grating, its applications, and why it is becoming a preferred choice among engineers and architects alike.

What is Fiberglass Grating?

Fiberglass grating is manufactured through a process called pultrusion, where continuous strands of glass fiber are pulled through a resin bath and then shaped into panels. These panels can be molded into various designs, with different levels of thickness, spacing, and load-bearing capabilities depending on the intended application. The result is a lightweight, durable material that offers excellent resistance to various environmental factors.

Advantages of Fiberglass Grating

1. Corrosion Resistance

One of the primary advantages of fiberglass grating is its exceptional resistance to corrosion. Unlike traditional metals, fiberglass does not rust when exposed to moisture or chemicals, making it ideal for environments such as chemical processing plants, wastewater treatment facilities, and coastal applications. This resistance significantly reduces maintenance costs and enhances the longevity of structures where it is employed.

2. Lightweight and Easy to Install

Fiberglass grating is considerably lighter than steel or aluminum grating, which simplifies transportation and installation. This lightweight nature reduces labor costs and minimizes the need for heavy lifting equipment during installation. Furthermore, the ease of handling fiberglass panels leads to quicker project completion times.

3. Slip Resistance

Safety is paramount in industrial settings, and fiberglass grating excels in providing slip-resistant surfaces. With its textured finish and inherent properties, it offers superior traction, even in wet or oily conditions. This is particularly beneficial in areas such as walkways, stairs, and platforms where slips and falls can pose significant hazards.

4. Fire Resistance

Fiberglass grating is classified as self-extinguishing and does not produce toxic smoke or harmful gases when exposed to fire. This characteristic is crucial for applications in industries where fire safety is a significant concern, including petrochemical facilities and power generation plants.

fiberglass grating

5. Customizability

Fiberglass grating can be customized to meet specific design and structural requirements. Engineers can choose from various panel sizes, colors, and surface textures, allowing for innovative designs that can enhance aesthetics while maintaining functionality. This versatility ensures that fiberglass grating can suit a wide range of architectural styles and industrial needs.

Applications of Fiberglass Grating

1. Industrial Facilities

Fiberglass grating is extensively used in industrial facilities, including chemical plants, food processing centers, and manufacturing plants. Its resistance to harsh chemicals and physical wear makes it an ideal choice for walkways, platforms, and load-bearing structures.

2. Marine and Coastal Environments

In marine applications, fiberglass grating is resistant to saltwater corrosion, making it perfect for docks, piers, and coastal walkways. Its slip-resistant surface is invaluable in these environments, where water exposure can create hazardous conditions.

3. Water Treatment Facilities

Wastewater treatment plants benefit from fiberglass grating's non-corrosive nature, making it ideal for use in corrosive environments where metal grating would deteriorate rapidly. The durability and easy maintenance of fiberglass make it a logical choice in this application.

4. Commercial Buildings

Fiberglass grating is also utilized in commercial construction, particularly for walkways, staircases, and balcony railings. Its aesthetic appeal combined with practical benefits allows architects to create visually striking designs that also prioritize safety.

Conclusion

In summary, fiberglass grating is a versatile material that offers numerous advantages over traditional construction materials. Its corrosion resistance, lightweight nature, slip resistance, fire safety, and customizability make it an ideal choice for a range of applications in industrial, marine, and commercial settings. As industries continue to prioritize safety, durability, and efficiency, fiberglass grating is poised to play an increasingly significant role in modern construction and design. Whether you are designing a new facility or upgrading existing infrastructure, considering fiberglass grating could lead to long-term benefits and cost savings.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024