loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

3 月 . 03, 2025 13:16

Back to list

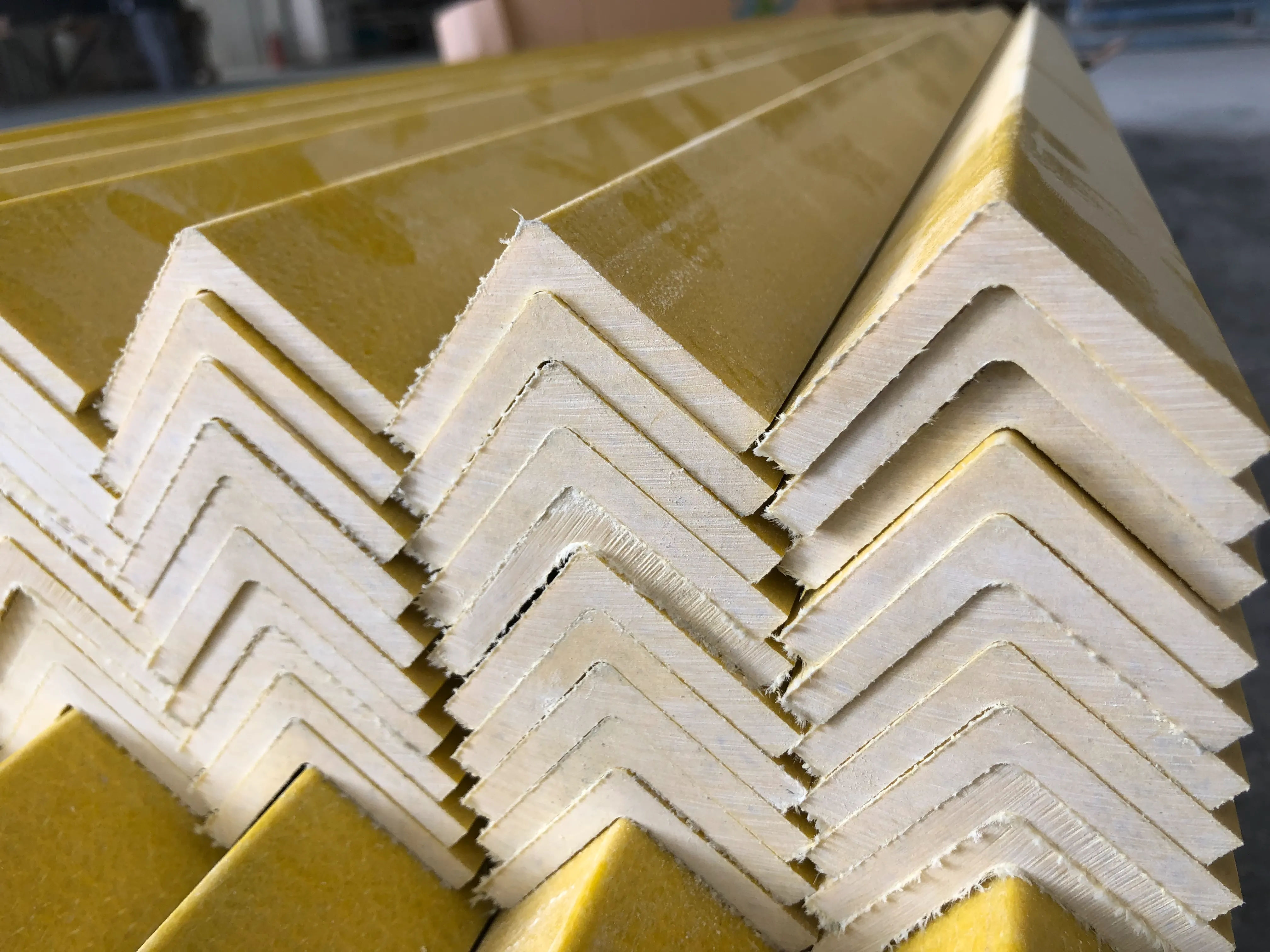

fiberglass grating for sale

In the modern industrial landscape, businesses are in a constant search for materials that can withstand harsh environments while providing versatility and reliability. Fiberglass grating has emerged as a popular choice for industries ranging from chemical processing to food production, and for a good reason. As someone with extensive experience in industrial materials, I can attest to the transformative impact fiberglass grating can have on operational efficiency and safety.

From a safety standpoint, fiberglass grating excels as well. Its slip-resistant surface is a critical feature in industries where wet conditions are prevalent. During my tenure overseeing safety standards in industrial setups, I noticed a tangible reduction in slip-and-fall incidents when fiberglass grating was installed. Its anti-slip surface, combined with its fire retardant properties, provides safety assurances that few other materials on the market can match. The versatility of fiberglass grating is further highlighted by its customization options. Available in various panel sizes, colors, and grating types, it can be tailored to meet specific project needs. Whether it's molded grating for heavy-duty applications or pultruded grating that offers higher load capacity, the adaptability of fiberglass gratings makes it suitable for a myriad of industrial applications. This customization empowers businesses to deploy a solution that aligns perfectly with their functional and aesthetic requirements. As an expert in the field, I frequently emphasize the importance of sourcing materials from reputable suppliers. The credibility of the manufacturer can significantly impact the quality of the fiberglass grating. Certification and compliance with industry standards are non-negotiable factors in ensuring the best performance from your purchase. Reputable suppliers also offer warranties and extensive product information, further reinforcing trust and confidence in their products. In sum, fiberglass grating presents a compelling case for inclusion in any industrial context. Its durability, safety features, and long-term cost benefits create an unmatched value proposition. For those seeking fiberglass grating for sale, informed purchasing decisions can lead to improved operational outcomes, reflecting not only on the bottom line but also on the overall workplace safety and productivity. By choosing fiberglass grating, businesses invest not just in a product, but also in a solution that aligns with the demands of modern industry challenges, providing a robust response to both current and future needs.

From a safety standpoint, fiberglass grating excels as well. Its slip-resistant surface is a critical feature in industries where wet conditions are prevalent. During my tenure overseeing safety standards in industrial setups, I noticed a tangible reduction in slip-and-fall incidents when fiberglass grating was installed. Its anti-slip surface, combined with its fire retardant properties, provides safety assurances that few other materials on the market can match. The versatility of fiberglass grating is further highlighted by its customization options. Available in various panel sizes, colors, and grating types, it can be tailored to meet specific project needs. Whether it's molded grating for heavy-duty applications or pultruded grating that offers higher load capacity, the adaptability of fiberglass gratings makes it suitable for a myriad of industrial applications. This customization empowers businesses to deploy a solution that aligns perfectly with their functional and aesthetic requirements. As an expert in the field, I frequently emphasize the importance of sourcing materials from reputable suppliers. The credibility of the manufacturer can significantly impact the quality of the fiberglass grating. Certification and compliance with industry standards are non-negotiable factors in ensuring the best performance from your purchase. Reputable suppliers also offer warranties and extensive product information, further reinforcing trust and confidence in their products. In sum, fiberglass grating presents a compelling case for inclusion in any industrial context. Its durability, safety features, and long-term cost benefits create an unmatched value proposition. For those seeking fiberglass grating for sale, informed purchasing decisions can lead to improved operational outcomes, reflecting not only on the bottom line but also on the overall workplace safety and productivity. By choosing fiberglass grating, businesses invest not just in a product, but also in a solution that aligns with the demands of modern industry challenges, providing a robust response to both current and future needs.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024