loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

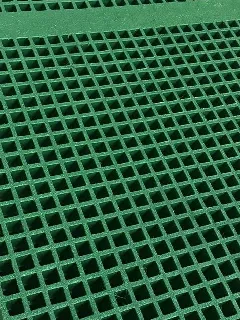

Durable and Lightweight Fiberglass Grating Solutions for Various Applications

Understanding Fiberglass Grating Panels A Comprehensive Overview

Fiberglass grating panels are becoming increasingly popular in various industries due to their unique properties and advantages. Made from a composite of fiberglass and resin, these panels offer durability, lightweight characteristics, and exceptional resistance to corrosion, making them suitable for a variety of applications. In this article, we will explore the features, benefits, and uses of fiberglass grating panels, highlighting why they are an optimal choice for many projects.

What Are Fiberglass Grating Panels?

Fiberglass grating panels consist of a network of fiberglass reinforced plastic (FRP) that is molded into a grid-like structure. The manufacturing process involves combining strands of fiberglass with a thermosetting resin, which is then cured to form a rigid material. The resulting panels are available in a range of sizes, colors, and configurations, allowing for customization to meet specific project requirements.

Advantages of Fiberglass Grating Panels

1. Corrosion Resistance One of the standout features of fiberglass grating panels is their outstanding resistance to chemicals and corrosive environments. Traditional materials like steel or aluminum can degrade over time when exposed to harsh substances, but fiberglass grating maintains its structural integrity, making it ideal for use in chemical plants, wastewater treatment facilities, and marine applications.

2. Lightweight yet Strong Fiberglass grating is significantly lighter than traditional steel grating, making it easier to transport and install. Despite its lightweight nature, it possesses excellent strength-to-weight ratios, allowing it to support heavy loads without compromising safety.

3. Safety Safety is a top priority in industrial settings, and fiberglass grating panels excel in this area. Their non-slip surfaces provide excellent traction, reducing the risk of slips and falls. Additionally, they are designed to resist impact and wear, contributing to long-term safety in high-traffic areas.

4. Low Maintenance Unlike metals that may require regular painting or rust prevention treatments, fiberglass grating panels are virtually maintenance-free. Their non-porous surfaces do not promote bacterial growth, making them easy to clean and suitable for sanitary environments.

5. Aesthetic Appeal While functionality is crucial, aesthetics should not be overlooked. Fiberglass grating panels can be produced in various colors and styles, allowing them to blend seamlessly into the existing architectural design of a facility.

fiberglass grating panels

Applications of Fiberglass Grating Panels

The versatility of fiberglass grating panels makes them suitable for numerous applications across diverse industries. Here are some common uses

1. Industrial Flooring Fiberglass grating panels are widely used for walkways, platforms, and workstations in industrial settings. Their strength and durability make them suitable for heavy machinery and foot traffic.

2. Water Treatment Facilities Due to their resistance to corrosion from chemicals in wastewater, fiberglass grating is commonly used in water treatment plants for walkways and drainage covers.

3. Marine Applications In marine environments, fiberglass grating panels are ideal for docks, piers, and boat ramps, where exposure to water and salt can quickly degrade traditional materials.

4. Food and Beverage Industry The sanitary properties of fiberglass gratings make them a popular choice in food processing facilities, where cleanliness and resistance to contaminants are paramount.

5. Oil and Gas Industry In the oil and gas sectors, fiberglass grating panels provide safe and effective flooring solutions in refineries and drilling sites, where exposure to chemicals is an ongoing concern.

Conclusion

Fiberglass grating panels are a superior alternative to traditional grating materials, thanks to their unique blend of durability, strength, and corrosion resistance. With an array of applications across various industries, they not only contribute to safety and efficiency but also enhance the aesthetic appeal of facilities. As industries continue to prioritize safety and cost-effectiveness, the demand for fiberglass grating panels is likely to grow, marking a significant trend in construction and industrial design. By choosing this innovative material, businesses can ensure longevity and reliability in their operations, setting a standard for quality in their respective fields.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024