loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 10, 2025 19:45

Back to list

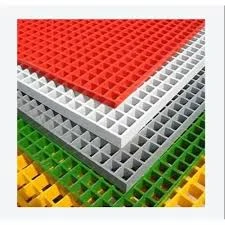

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Navigating the realm of safety and durability in construction and industrial environments requires a keen understanding of materials used in infrastructure. One such material, fiberglass grating stair treads, has emerged as a quintessential choice for industries demanding high safety standards and long-term performance. The unique combination of properties such as corrosion resistance, lightweight, and non-conductivity makes fiberglass grating stair treads unrivaled in various applications. Here’s why incorporating them into your projects could be a transformative decision.

The versatility and adaptability of fiberglass grating stair treads also merit attention. Available in a variety of sizes and shapes, they can be customized to fit unique architectural designs and specific operational needs. This adaptability ensures that the integrity of design aesthetics is maintained while reaping functional benefits. Engineers and architects can order treads that precisely fit the required specifications, ensuring seamless integration into existing structures without significant alterations. In terms of sustainability, fiberglass grating stair treads outshine many of their counterparts. Their long life cycle and the reduction in manufacturing emissions compared to metal production posit them as an environmentally friendly option. Organizations aiming to reduce their carbon footprint will find fiberglass treads aligning with their sustainability goals. By choosing this eco-friendly alternative, businesses can enhance their environmental stewardship and appeal to environmentally conscious stakeholders. Finally, the light weight of fiberglass grating stair treads should not be overlooked. This feature simplifies installation, reduces transportation costs, and facilitates easy on-site modifications. Contractors and builders are able to complete projects more efficiently, translating into cost savings and rapid project turnarounds. The ease of installation without the need for heavy lifting equipment further underscores their practicality in challenging settings. In conclusion, fiberglass grating stair treads represent a fusion of safety, durability, and adaptability. For industries and environments that prioritize these characteristics, this innovative solution provides a reliable pathway to maintaining high standards of operational safety and performance while embracing modern engineering solutions.

The versatility and adaptability of fiberglass grating stair treads also merit attention. Available in a variety of sizes and shapes, they can be customized to fit unique architectural designs and specific operational needs. This adaptability ensures that the integrity of design aesthetics is maintained while reaping functional benefits. Engineers and architects can order treads that precisely fit the required specifications, ensuring seamless integration into existing structures without significant alterations. In terms of sustainability, fiberglass grating stair treads outshine many of their counterparts. Their long life cycle and the reduction in manufacturing emissions compared to metal production posit them as an environmentally friendly option. Organizations aiming to reduce their carbon footprint will find fiberglass treads aligning with their sustainability goals. By choosing this eco-friendly alternative, businesses can enhance their environmental stewardship and appeal to environmentally conscious stakeholders. Finally, the light weight of fiberglass grating stair treads should not be overlooked. This feature simplifies installation, reduces transportation costs, and facilitates easy on-site modifications. Contractors and builders are able to complete projects more efficiently, translating into cost savings and rapid project turnarounds. The ease of installation without the need for heavy lifting equipment further underscores their practicality in challenging settings. In conclusion, fiberglass grating stair treads represent a fusion of safety, durability, and adaptability. For industries and environments that prioritize these characteristics, this innovative solution provides a reliable pathway to maintaining high standards of operational safety and performance while embracing modern engineering solutions.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024