loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

fiberglass rebar cost

The Cost of Fiberglass Rebar An In-Depth Analysis

In the construction industry, choosing the right materials is crucial for ensuring durability, safety, and cost-effectiveness. One such material that has gained traction in recent years is fiberglass rebar. Unlike traditional steel rebar, fiberglass rebar offers numerous advantages, including resistance to corrosion, reduced weight, and ease of handling. However, a significant consideration for builders and contractors is the cost associated with fiberglass rebar. In this article, we will explore the factors that influence the pricing of fiberglass rebar and its overall economic impact on construction projects.

Understanding Fiberglass Rebar

Fiberglass rebar, also known as glass-fiber reinforced polymer (GFRP) rebar, is made from a combination of glass fibers and resin. This composite material is designed to offer enhanced performance characteristics compared to conventional steel rebar. The main benefits of fiberglass rebar include

1. Corrosion Resistance Fiberglass rebar does not rust or corrode, making it ideal for use in harsh environments, such as coastal areas or applications involving salts and chemicals. This attribute significantly extends the lifespan of structures, reducing long-term maintenance and replacement costs.

2. Lightweight Fiberglass rebar is approximately one-quarter the weight of steel rebar, which can lead to reduced transportation costs and easier handling on site. This can result in decreased labor expenses and improved safety during installation.

3. Non-Magnetic The non-magnetic nature of fiberglass rebar makes it suitable for use in applications where electromagnetic interference needs to be minimized, such as in certain types of electronic facilities.

Factors Influencing Cost

While fiberglass rebar provides numerous benefits, its cost is typically higher than that of traditional steel rebar. Several factors contribute to the pricing of fiberglass rebar

fiberglass rebar cost

1. Material Composition The quality and type of glass fibers used in the production of fiberglass rebar can impact costs. High-quality fibers and specialized resins can drive the price up, but they also enhance the performance characteristics of the final product.

2. Manufacturing Process The production process for fiberglass rebar is more complex than that for steel rebar. The need for specialized equipment and skilled labor in the manufacturing process can lead to increased costs.

3. Market Demand As awareness of fiberglass rebar’s benefits increases, so does its demand. Market fluctuations—driven by construction industry trends or economic conditions—can influence the price of fiberglass rebar.

4. Availability Fiberglass rebar may not be as widely available as steel rebar, particularly in certain regions. Limited supply can lead to higher prices, especially in areas where there is greater demand for innovative construction materials.

Cost-Benefit Analysis

When considering the cost of fiberglass rebar, it is essential to conduct a cost-benefit analysis. While initial expenses may be higher compared to traditional steel rebar, the long-term savings can be substantial. The durability and corrosion resistance of fiberglass rebar can lead to lower maintenance costs over time, making it a more cost-effective choice for specific applications.

For example, in infrastructure projects such as bridges, tunnels, and coastal structures where exposure to moisture and chemicals is prevalent, the investment in fiberglass rebar can pay dividends in terms of longevity and reduced upkeep. Additionally, the reduced weight of fiberglass rebar can lower transportation and labor costs, further enhancing its economical advantages.

Conclusion

In summary, the cost of fiberglass rebar is influenced by various factors, including material quality, manufacturing processes, market demand, and availability. While it may have a higher upfront cost compared to traditional steel rebar, the long-term benefits—including resistance to corrosion, weight savings, and reduced maintenance—can result in significant overall savings. As the construction industry continues to evolve, the adoption of innovative materials like fiberglass rebar may play a pivotal role in enhancing project sustainability and cost-effectiveness. For contractors and builders, understanding the full economic impact is essential when making material choices for their projects.

-

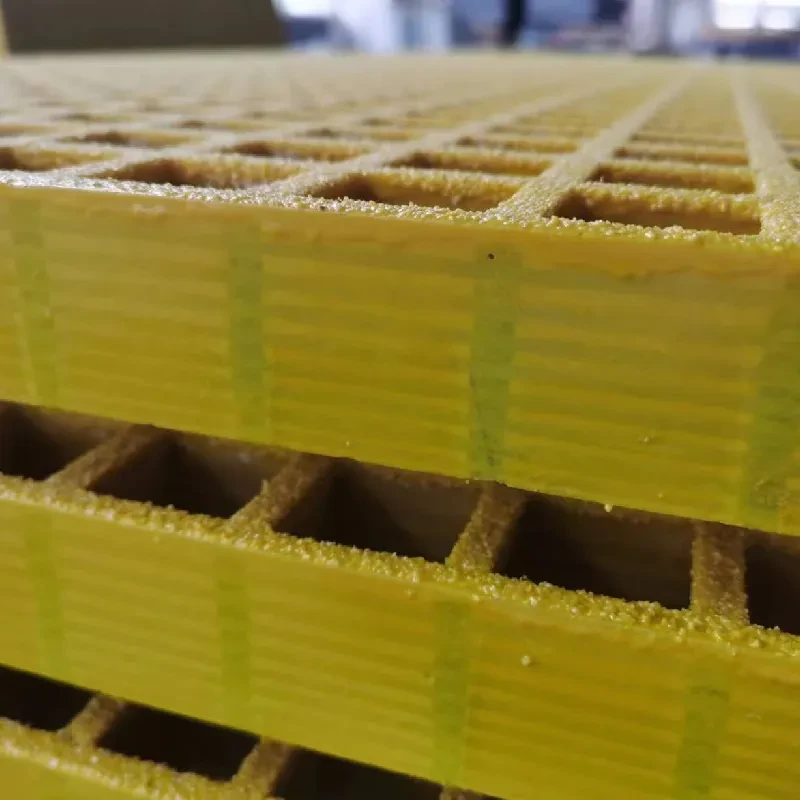

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024