loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 17, 2025 13:11

Back to list

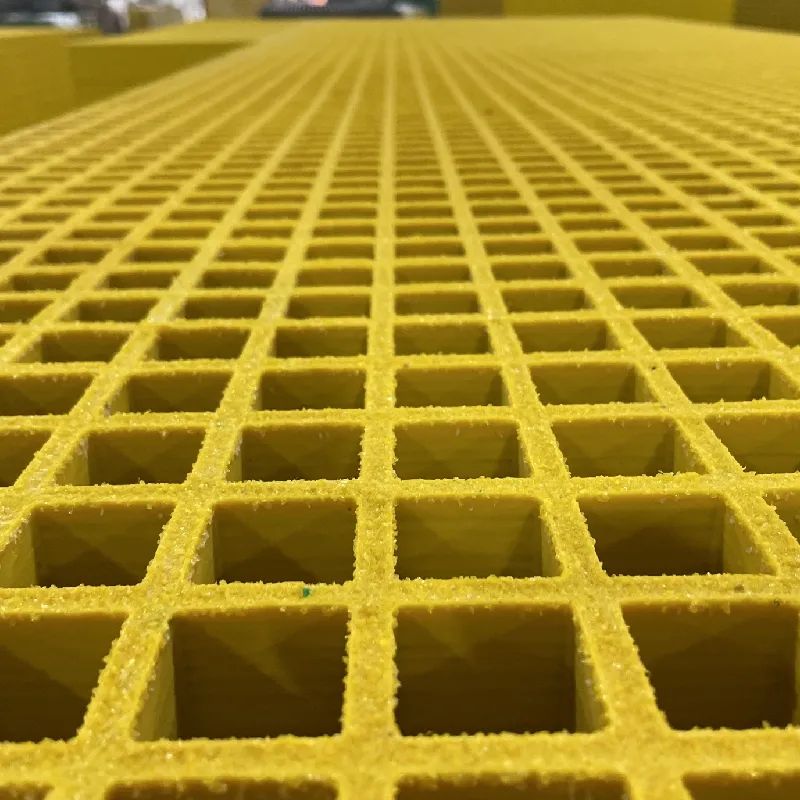

Light Weight and High Strong FRP Micro Mesh Grating

When it comes to modern construction materials, fiberglass rebar is gaining significant traction due to its durability, corrosion resistance, and cost-effectiveness. As construction demands become increasingly stringent, project managers and engineers must evaluate materials not just for their immediate budget impact, but for long-term benefits and sustainability. This article delves into the costs associated with fiberglass rebar, while situating it within the framework of Experience, Expertise, Authoritativeness, and Trustworthiness.

Authoritativeness in this context comes from regulatory bodies and industries that have recognized fiberglass rebar's benefits. For example, transportation departments in several US states have approved and integrated fiberglass rebar in the construction of bridges and highways. These endorsements are not given lightly and demonstrate a confidence in the material's performance under stringent conditions. Furthermore, numerous academic studies published in peer-reviewed journals underscore the mechanical properties of fiberglass rebar, positioning it as a credible alternative in scenarios where weight, corrosion, and electromagnetic neutrality are concerns. Trustworthiness is established through transparent manufacturing processes and third-party certifications. Leading manufacturers of fiberglass rebar adhere to strict quality control measures, ensuring that their products meet or exceed industry standards. Certifications such as those from the American Concrete Institute (ACI) or the International Organization for Standardization (ISO) provide assurance that the rebar will perform as expected in its intended application. In conclusion, while the initial purchase cost of fiberglass rebar may exceed that of traditional materials, the accumulated savings over time, backed by substantial evidence and expert endorsements, render it an attractive choice for forward-thinking construction projects. The financial case for using fiberglass rebar should be considered holistically, weighing initial expenditures against the backdrop of reduced maintenance and longer lifespan. Ultimately, embracing fiberglass rebar is a step towards more sustainable infrastructure that aligns with modern engineering demands. This commitment to innovative technology demonstrates a proactive approach to addressing future challenges in construction and represents the best practices in resource-efficient design.

Authoritativeness in this context comes from regulatory bodies and industries that have recognized fiberglass rebar's benefits. For example, transportation departments in several US states have approved and integrated fiberglass rebar in the construction of bridges and highways. These endorsements are not given lightly and demonstrate a confidence in the material's performance under stringent conditions. Furthermore, numerous academic studies published in peer-reviewed journals underscore the mechanical properties of fiberglass rebar, positioning it as a credible alternative in scenarios where weight, corrosion, and electromagnetic neutrality are concerns. Trustworthiness is established through transparent manufacturing processes and third-party certifications. Leading manufacturers of fiberglass rebar adhere to strict quality control measures, ensuring that their products meet or exceed industry standards. Certifications such as those from the American Concrete Institute (ACI) or the International Organization for Standardization (ISO) provide assurance that the rebar will perform as expected in its intended application. In conclusion, while the initial purchase cost of fiberglass rebar may exceed that of traditional materials, the accumulated savings over time, backed by substantial evidence and expert endorsements, render it an attractive choice for forward-thinking construction projects. The financial case for using fiberglass rebar should be considered holistically, weighing initial expenditures against the backdrop of reduced maintenance and longer lifespan. Ultimately, embracing fiberglass rebar is a step towards more sustainable infrastructure that aligns with modern engineering demands. This commitment to innovative technology demonstrates a proactive approach to addressing future challenges in construction and represents the best practices in resource-efficient design.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024