loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 03, 2025 04:20

Back to list

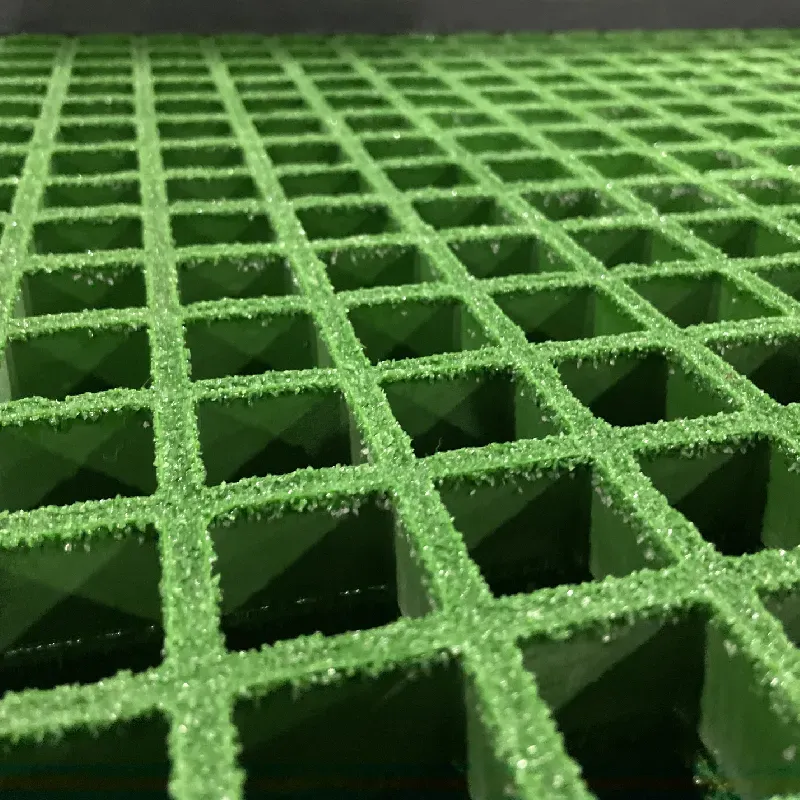

Corrosion Resistant and Slip Resistant FRP GRP Fiberglass Covered Grating

Fiberglass rebar has emerged as a game-changer in the construction sector, providing an innovative alternative to traditional steel reinforcements. As the demand for sustainable and durable construction materials grows, fiberglass rebar manufacturers worldwide are stepping up to meet this need, offering products that promise enhanced longevity, strength, and resistance against corrosion. Delving into the intricacies of this burgeoning market reveals why fiberglass rebar manufacturers are poised at the forefront of construction innovation.

One of the hallmark characteristics of a reputable fiberglass rebar manufacturer is their commitment to customer education and service. These companies often provide extensive support to construction engineers and architects, offering guidance on best practices for integrating fiberglass rebar into building designs. Workshops, seminars, and comprehensive product catalogs are part of the package, ensuring clients are fully informed and confident in their choice of materials. This level of engagement and transparency fosters trust and cultivates long-term relationships between manufacturers and their clients. In terms of authority, many fiberglass rebar manufacturers are key players in shaping the future of construction materials. Through collaborations with academic institutions and industry bodies, they drive forward research that influences construction standards and practices. Their participation in technical committees and conferences underscores their commitment to advancing the use of fiberglass rebar globally, pushing the envelope on what's possible in construction innovation. Trust is a fundamental element when deciding on a fiberglass rebar manufacturer. Trustworthiness is built through consistency in product quality and reliability in supply. Manufacturers who offer assurances such as warranties demonstrate confidence in their products. Furthermore, positive client testimonials and case studies serve as endorsements, highlighting the successful application of fiberglass rebar across various projects and climates. In conclusion, the realm of fiberglass rebar manufacturers is populated by firms that exemplify experience, expertise, authoritativeness, and trustworthiness. These companies are redefining the landscape of construction materials, offering products that promise not only enhanced performance and sustainability but also a forward-thinking approach to building design. As the industry continues to evolve, the role of these manufacturers will undoubtedly become even more integral, shaping the future of how we construct our world. Through continuous innovation and commitment to quality, fiberglass rebar manufacturers are essential partners in the pursuit of resilient and sustainable infrastructure.

One of the hallmark characteristics of a reputable fiberglass rebar manufacturer is their commitment to customer education and service. These companies often provide extensive support to construction engineers and architects, offering guidance on best practices for integrating fiberglass rebar into building designs. Workshops, seminars, and comprehensive product catalogs are part of the package, ensuring clients are fully informed and confident in their choice of materials. This level of engagement and transparency fosters trust and cultivates long-term relationships between manufacturers and their clients. In terms of authority, many fiberglass rebar manufacturers are key players in shaping the future of construction materials. Through collaborations with academic institutions and industry bodies, they drive forward research that influences construction standards and practices. Their participation in technical committees and conferences underscores their commitment to advancing the use of fiberglass rebar globally, pushing the envelope on what's possible in construction innovation. Trust is a fundamental element when deciding on a fiberglass rebar manufacturer. Trustworthiness is built through consistency in product quality and reliability in supply. Manufacturers who offer assurances such as warranties demonstrate confidence in their products. Furthermore, positive client testimonials and case studies serve as endorsements, highlighting the successful application of fiberglass rebar across various projects and climates. In conclusion, the realm of fiberglass rebar manufacturers is populated by firms that exemplify experience, expertise, authoritativeness, and trustworthiness. These companies are redefining the landscape of construction materials, offering products that promise not only enhanced performance and sustainability but also a forward-thinking approach to building design. As the industry continues to evolve, the role of these manufacturers will undoubtedly become even more integral, shaping the future of how we construct our world. Through continuous innovation and commitment to quality, fiberglass rebar manufacturers are essential partners in the pursuit of resilient and sustainable infrastructure.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024