loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

fiberglass reinforced plastic grating

Fiberglass Reinforced Plastic Grating A Comprehensive Overview

Fiberglass reinforced plastic (FRP) grating is an innovative and highly versatile material that has gained significant traction across various industries over the past few decades. Its unique properties make it ideal for applications where traditional materials like steel or wood might fall short. This article delves into the characteristics, advantages, applications, and Future of FRP grating, shedding light on why it has become a preferred choice for engineers and architects alike.

What is FRP Grating?

At its core, fiberglass reinforced plastic grating is a composite material formed by combining fiberglass with a resin matrix. The process involves embedding glass fibers within a polymer resin, which provides the grating with enhanced strength and durability. The result is a lightweight yet incredibly strong product that can withstand considerable loads and resist environmental degradation.

One of the defining features of FRP grating is its non-corrosive nature. Unlike traditional metal gratings that can rust and deteriorate when exposed to moisture, the non-metallic composition of FRP ensures longevity, making it an excellent choice for use in harsh conditions.

Key Advantages of FRP Grating

1. Corrosion Resistance FRP grating is inherently resistant to a wide variety of corrosive substances, including acids and alkalis. This property makes it particularly valuable in industries such as chemical processing, wastewater treatment, and marine applications.

2. Lightweight Compared to steel and concrete alternatives, FRP grating is significantly lighter, which simplifies installation and reduces transportation costs. This lightweight characteristic also makes it easier to handle, reducing the risk of injury during installation.

3. Strength and Durability Despite being lightweight, FRP grating can support heavy loads and endure high-stress environments. This strength is particularly beneficial in applications like flooring for industrial plants, walkways, and platforms that may be exposed to regular foot traffic or heavy machinery.

4. Slip Resistance FRP grating is designed to minimize slip hazards. The surface can be manufactured with various textures, providing excellent traction even when wet, making it a safe option for environments prone to spills or moisture.

fiberglass reinforced plastic grating

5. Easy Maintenance One of the significant advantages of FRP grating is its low maintenance requirement. Unlike wood, which may need regular treatments to prevent decay, or steel, which may need repainting to prevent rust, FRP solutions typically require only occasional cleaning to remove dirt and debris.

Applications of FRP Grating

The applications for FRP grating are vast and varied, catering to numerous sectors, including

- Industrial Plants Commonly used for platforms, walkways, and stairways where chemical exposure is a concern. - Water and Wastewater Treatment Ideal for applications where corrosion resistance is critical, such as chemical dosing stations and clarifiers. - Marine Environments Used extensively in shipbuilding and offshore infrastructure due to its resistance to saltwater and other corrosive agents. - Pulp and Paper Industry Often employed in facilities that handle caustic chemicals, FRP grating helps maintain structural integrity despite harsh conditions. - Food Processing Plants Since it can be manufactured to meet hygiene standards, it serves as flooring in environments where sanitation is critical.

Future of FRP Grating

The future of fiberglass reinforced plastic grating looks promising. As industries increasingly emphasize safety, durability, and sustainability, FRP grating stands out as a viable solution that meets these criteria. Innovations in manufacturing processes and advances in material technology will likely lead to even higher performance standards and greater versatility in applications.

Moreover, with the global push toward eco-friendliness, FRP’s lower environmental impact—thanks to its longevity and reduced need for replacements—will continue to make it an appealing alternative to traditional materials.

Conclusion

Fiberglass reinforced plastic grating represents a convergence of innovation and practicality. Its myriad benefits—corrosion resistance, lightweight, strength, and low maintenance—make it a material of choice for countless applications across diverse industries. As technology evolves and sustainability becomes increasingly prioritized, FRP grating is set to play an integral role in modern construction and industrial applications, marking a significant step forward in material innovation.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

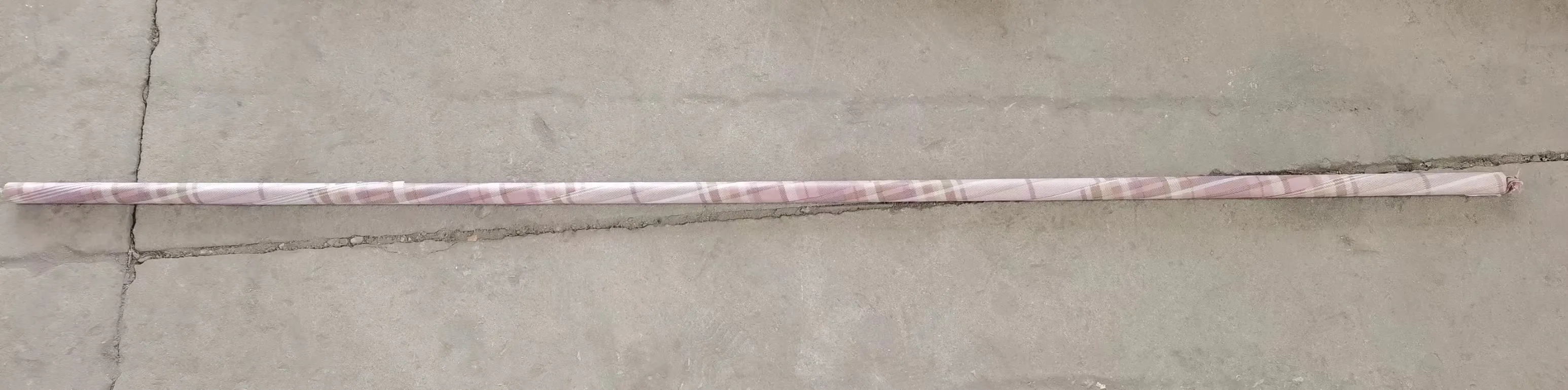

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024