loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

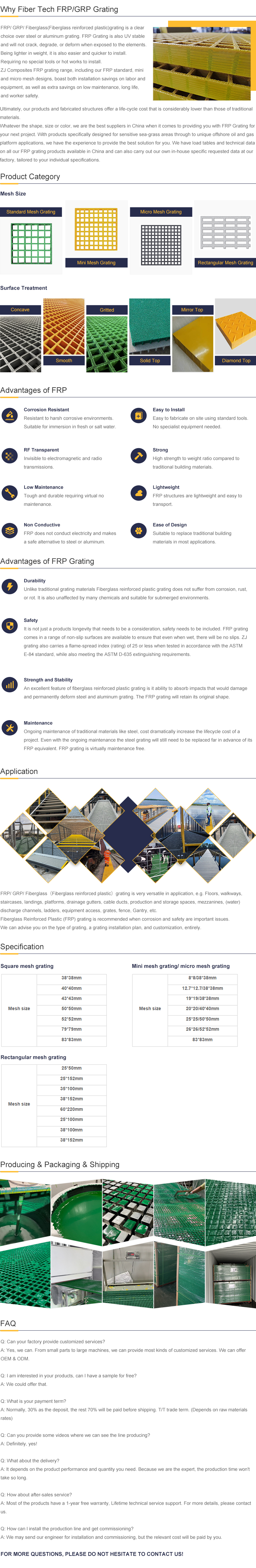

Durable Fiber-Reinforced Plastic Grating for Industrial Applications and Construction Use

Fiberglass Reinforced Plastic Grating A Versatile Solution for Modern Industries

Fiberglass reinforced plastic (FRP) grating has emerged as a preferred material in various industrial applications due to its unique combination of strength, durability, and lightweight properties. This innovative material is composed of a fiberglass matrix combined with a resin, which creates an exceptionally strong and rigid structure. As industries increasingly prioritize safety, efficiency, and sustainability, FRP grating offers a myriad of advantages that make it an ideal choice for diverse environments.

Fiberglass Reinforced Plastic Grating A Versatile Solution for Modern Industries

In addition to its corrosion resistance, FRP grating is also remarkably lightweight. The reduced weight makes it easier to handle and install compared to heavier materials. This attribute not only reduces labor costs but also minimizes transportation expenses. Moreover, the lightweight nature of FRP grating alleviates the structural load on support systems, allowing for the design of lighter yet structurally sound frameworks. This can be particularly beneficial in retrofitting older structures where additional load capabilities are critical.

fiberglass reinforced plastic grating

Safety is another paramount concern in many working environments, and FRP grating addresses this issue effectively. The surface of FRP grating can be designed to be slip-resistant, significantly reducing the risk of accidents in areas prone to spills or moisture. This characteristic is crucial in settings like industrial plants, kitchens, and outdoor walkways where the potential for slips and falls exists. Additionally, the grating is often designed with a fire-retardant resin, which enhances safety in areas where fire hazards are a concern.

The versatility of FRP grating allows it to be tailored to meet specific requirements. Available in various shapes, sizes, and colors, it can be customized to suit a range of applications, from pedestrian walkways and platforms to heavy-duty industrial flooring. The adaptability of FRP grating makes it suitable for both indoor and outdoor use, further expanding its applicability across numerous sectors.

Environmental sustainability is another compelling reason to choose FRP grating. The manufacturing process of fiberglass has been deemed less energy-intensive compared to traditional metal production. Furthermore, FRP is often produced using recyclable materials, and the end-of-life options for fiberglass products are becoming increasingly eco-friendly, with many manufacturers recycling or repurposing used materials. By opting for FRP grating, industries can demonstrate their commitment to sustainable practices while benefiting from high-performance materials.

In conclusion, fiberglass reinforced plastic grating presents an optimal solution for modern industries seeking durable, safe, and environmentally friendly flooring options. Its corrosion resistance, lightweight nature, slip-resistant surfaces, and customization capabilities make it invaluable in various settings, from chemical plants to public infrastructures. As businesses continue to prioritize efficiency and sustainability, the adoption of FRP grating is likely to increase, paving the way for safer working environments and reduced operational costs. By investing in this advanced material, industries can achieve long-lasting performance while contributing positively to their ecological footprints.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024