loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 17, 2025 03:04

Back to list

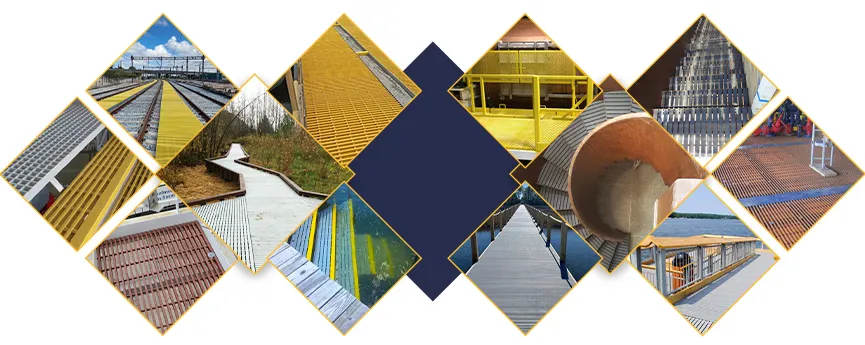

frp micro mesh grating

Fiberglass reinforced plastic (FRP) grating has become an essential component in a wide array of industries, thanks to its unique set of properties that make it superior to traditional materials such as steel or aluminum. Based on extensive firsthand experience in the field, FRP grating offers unparalleled benefits in terms of durability, safety, and cost-efficiency.

Another factor contributing to the authority of FRP grating in various sectors is its long lifespan. Unlike traditional materials that require frequent replacements or repairs, FRP grating offers an exceptional lifecycle. This longevity not only translates to significant cost savings over time but also minimizes environmental impact by reducing waste and the need for constant resource extraction. When discussing trustworthiness, case studies and real-world applications of FRP grating further solidify its reputation. Numerous industries, from petrochemical to wastewater treatment facilities, have reported remarkable performance results. These include improved operational efficiency, enhanced safety records, and commendable return on investment. The growing adoption of FRP grating across the globe is a testament to its reliability and the positive experiences shared by industry experts. Importantly, many suppliers of FRP grating provide comprehensive service packages, from design consultation to aftersales support, ensuring clients receive expert guidance throughout the process. This commitment to customer satisfaction and continuous improvement reflects the dedication of the industry to uphold high standards and instill confidence in end-users. In conclusion, fiberglass reinforced plastic grating represents a modern solution to age-old challenges in construction and industrial settings. Its innovative design and versatile application, backed by expert knowledge and authoritative case studies, position it as a preferred material choice for professionals seeking efficiency, safety, and sustainability. As industries evolve and demand materials that can endure challenging environments while offering economic and practical benefits, FRP grating emerges as the answer, proving that new materials can redefine traditional approaches to infrastructure and safety.

Another factor contributing to the authority of FRP grating in various sectors is its long lifespan. Unlike traditional materials that require frequent replacements or repairs, FRP grating offers an exceptional lifecycle. This longevity not only translates to significant cost savings over time but also minimizes environmental impact by reducing waste and the need for constant resource extraction. When discussing trustworthiness, case studies and real-world applications of FRP grating further solidify its reputation. Numerous industries, from petrochemical to wastewater treatment facilities, have reported remarkable performance results. These include improved operational efficiency, enhanced safety records, and commendable return on investment. The growing adoption of FRP grating across the globe is a testament to its reliability and the positive experiences shared by industry experts. Importantly, many suppliers of FRP grating provide comprehensive service packages, from design consultation to aftersales support, ensuring clients receive expert guidance throughout the process. This commitment to customer satisfaction and continuous improvement reflects the dedication of the industry to uphold high standards and instill confidence in end-users. In conclusion, fiberglass reinforced plastic grating represents a modern solution to age-old challenges in construction and industrial settings. Its innovative design and versatile application, backed by expert knowledge and authoritative case studies, position it as a preferred material choice for professionals seeking efficiency, safety, and sustainability. As industries evolve and demand materials that can endure challenging environments while offering economic and practical benefits, FRP grating emerges as the answer, proving that new materials can redefine traditional approaches to infrastructure and safety.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024