loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 15, 2025 09:58

Back to list

Long Lasting Sanitary SMC FRP Storage Water Tank

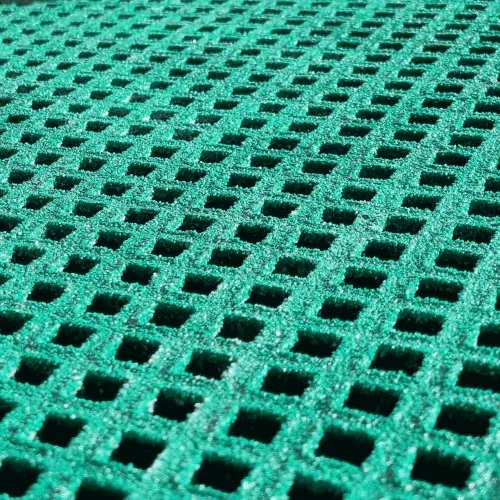

When it comes to creating safe, durable, and efficient staircases in industrial and commercial settings, one product stands out fibergrate stair treads. These innovative components offer an array of benefits over traditional materials, providing not only enhanced functionality but unparalleled reliability across various applications.

Expert engineers often highlight the versatility of fibergrate stair treads in design flexibility. These treads can be easily fabricated to fit specific dimensions and configurations, accommodating various building codes and aesthetic preferences. This adaptability allows architects and contractors to seamlessly integrate the treads into new construction projects or retrofit existing structures with minimal disruption. In terms of reliability, fibergrate stair treads maintain their structural integrity and appearance, even under heavy foot traffic and challenging environmental conditions. The inherent resilience of the material ensures that it remains functional and visually appealing throughout its service life, reinforcing trust in its performance. Industries ranging from manufacturing to marine rely on these treads for consistently safe and efficient access solutions. Given the ongoing emphasis on sustainability and environmentally-friendly construction practices, fibergrate stair treads also contribute positively by utilizing materials and production processes that minimize environmental impact. Many producers of these composite materials adhere to stringent environmental guidelines, ensuring that their products meet increasing demands for greener building solutions. In conclusion, the expertise and authority established by fibergrate stair treads in the industry are a testament to their superior performance and dependability. Whether prioritized for their safety features, cost-effectiveness, longevity, or environmental benefits, these stair treads represent a wise investment for any facility seeking to enhance its infrastructure. Facility managers, safety officers, and architects can place their trust in the robust qualities of fibergrate stair treads, knowing that they are utilizing a product that not only meets but exceeds modern standards of excellence in building design and safety.

Expert engineers often highlight the versatility of fibergrate stair treads in design flexibility. These treads can be easily fabricated to fit specific dimensions and configurations, accommodating various building codes and aesthetic preferences. This adaptability allows architects and contractors to seamlessly integrate the treads into new construction projects or retrofit existing structures with minimal disruption. In terms of reliability, fibergrate stair treads maintain their structural integrity and appearance, even under heavy foot traffic and challenging environmental conditions. The inherent resilience of the material ensures that it remains functional and visually appealing throughout its service life, reinforcing trust in its performance. Industries ranging from manufacturing to marine rely on these treads for consistently safe and efficient access solutions. Given the ongoing emphasis on sustainability and environmentally-friendly construction practices, fibergrate stair treads also contribute positively by utilizing materials and production processes that minimize environmental impact. Many producers of these composite materials adhere to stringent environmental guidelines, ensuring that their products meet increasing demands for greener building solutions. In conclusion, the expertise and authority established by fibergrate stair treads in the industry are a testament to their superior performance and dependability. Whether prioritized for their safety features, cost-effectiveness, longevity, or environmental benefits, these stair treads represent a wise investment for any facility seeking to enhance its infrastructure. Facility managers, safety officers, and architects can place their trust in the robust qualities of fibergrate stair treads, knowing that they are utilizing a product that not only meets but exceeds modern standards of excellence in building design and safety.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024