loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

fiber reinforced plastic rod

Fiber Reinforced Plastic Rods Advancements and Applications

Fiber reinforced plastic (FRP) rods are emerging as a transformative solution across various industries, thanks to their lightweight yet robust characteristics. These rods, composed of a plastic matrix reinforced with fibers such as glass, carbon, or aramid, offer numerous advantages over traditional materials like metal and wood. In this article, we will explore the composition, benefits, and applications of FRP rods.

Composition and Manufacturing

Fiber reinforced plastic rods are created by combining fibers with a polymer resin. The choice of fiber significantly influences the properties of the final product. Glass fibers are commonly used due to their excellent tensile strength and cost-effectiveness. Carbon fibers offer superior strength-to-weight ratios, making them ideal for high-performance applications. Aramid fibers, known for their outstanding impact resistance, are applied in situations demanding high durability.

The manufacturing process typically involves pultrusion or filament winding. In pultrusion, continuous fibers are drawn through a resin bath and then heated, curing the resin and creating a solid rod. Filament winding, on the other hand, winds fibers around a rotating mandrel to create a hollow shape. Both methods allow for precise control over dimensions and fiber orientation, ensuring that the final product meets specific performance requirements.

Advantages of FRP Rods

One of the most significant benefits of FRP rods is their high strength-to-weight ratio. They are considerably lighter than metal counterparts, reducing transportation costs and allowing for easier installation. Additionally, FRP rods are resistant to corrosion, which makes them suitable for use in harsh environments. They do not rust, rot, or degrade over time, making them a long-lasting alternative.

fiber reinforced plastic rod

Furthermore, FRP rods exhibit excellent electrical insulation properties, making them ideal for applications in electrical and telecommunications sectors. Their thermal stability and resistance to UV radiation enhance their performance in outdoor environments, ensuring longevity.

Applications of FRP Rods

The versatility of fiber reinforced plastic rods allows for their use across a wide range of fields. In the construction industry, they are utilized as reinforcement in concrete structures, providing enhanced durability and load-bearing capacity. Their lightweight nature also facilitates the construction of bridges and other infrastructures where reducing weight is crucial.

In the aerospace and automotive industries, FRP rods contribute to the design of lightweight, fuel-efficient vehicles. Their application extends to sports equipment, where high-performance designs benefit from the strength and low weight of FRP materials.

Additionally, the medical field is increasingly adopting FRP rods for prosthetics and orthopedic devices, where customization and high strength are required. The scope of FRP rods continues to expand, with ongoing research and innovations aimed at improving their performance and sustainability.

Conclusion

Fiber reinforced plastic rods represent a significant leap forward in material technology, offering unparalleled advantages across various industries. Their lightweight, corrosion-resistant, and strong nature positions them as a preferred choice for applications ranging from construction to aerospace. As advancements in FRP technology continue, the possibilities for their use will undoubtedly grow, paving the way for innovative solutions in the future.

-

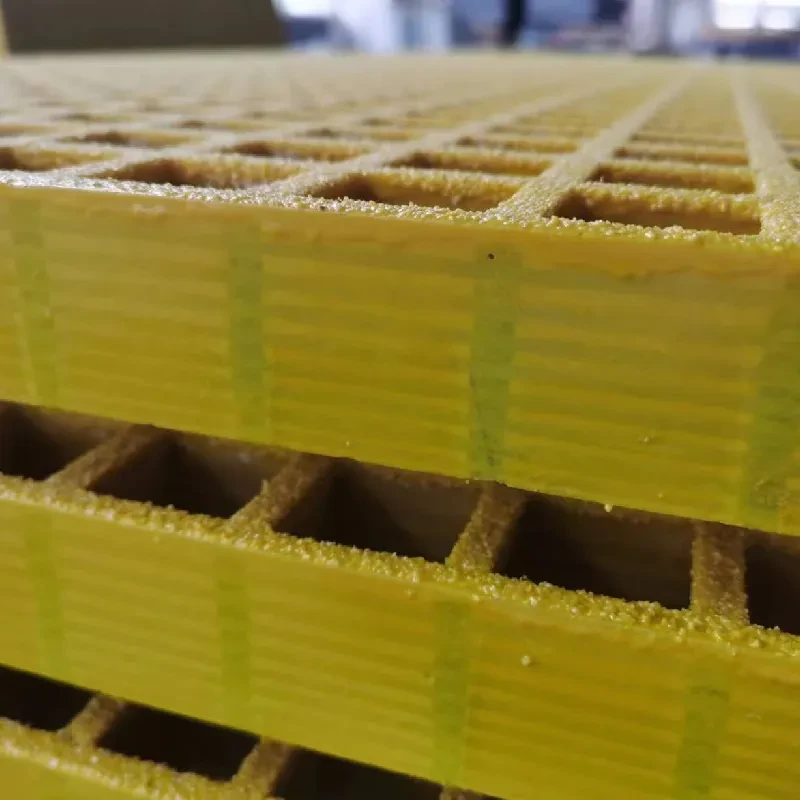

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024