loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 03, 2025 00:35

Back to list

fiber reinforced plastic rod

Fiber reinforced plastic (FRP) rods represent a cutting-edge solution increasingly recognized for their unparalleled performance in a wide range of industrial applications. With decades of development driven by innovation, these composite materials have continuously proven crucial in sectors requiring high strength-to-weight ratios, corrosion resistance, and electrical non-conductivity. My experience as a materials engineer positions me to delve into the nuanced benefits and applications of FRP rods, a topic where expertise and commitment to quality meet.

Trustworthiness in material consistency and product delivery is another pivotal factor driving the adoption of FRP rods. Rigorous quality standards govern the manufacturing process, ensuring each rod adheres to strict performance criteria. Industry certifications and endorsements further bolster confidence amongst stakeholders that these materials will perform as intended under specified conditions. It's important to highlight the sustainability aspect of using FRP rods. The life cycle assessment of these materials shows significant advantages over traditional options. With lower environmental impacts due to enhanced longevity and reduced maintenance requirements, FRP rods resonate with today's drive towards more sustainable construction practices. A foray into fields like renewable energy further underscores the authoritative role FRP rods play. In wind turbine construction, for example, the need for materials that are not only strong but also lightweight becomes clear. FRP rods fit this requirement perfectly, supporting turbine blades that must endure extreme stresses and weather conditions while minimizing weight to maximize efficiency. Ultimately, fiber reinforced plastic rods represent a fusion of advanced engineering and reliability, setting new standards across diverse industries. Their role is that of an enabler, paving the way for innovative designs and long-lasting solutions. As industry requirements evolve, one can anticipate further advancements in FRP technology, driving even greater adoption rates. Through firsthand experience, comprehensive expertise, and unwavering authority in the field, it’s evident that FRP rods are not only a practical solution but also a testament to the relentless pursuit of engineering excellence.

Trustworthiness in material consistency and product delivery is another pivotal factor driving the adoption of FRP rods. Rigorous quality standards govern the manufacturing process, ensuring each rod adheres to strict performance criteria. Industry certifications and endorsements further bolster confidence amongst stakeholders that these materials will perform as intended under specified conditions. It's important to highlight the sustainability aspect of using FRP rods. The life cycle assessment of these materials shows significant advantages over traditional options. With lower environmental impacts due to enhanced longevity and reduced maintenance requirements, FRP rods resonate with today's drive towards more sustainable construction practices. A foray into fields like renewable energy further underscores the authoritative role FRP rods play. In wind turbine construction, for example, the need for materials that are not only strong but also lightweight becomes clear. FRP rods fit this requirement perfectly, supporting turbine blades that must endure extreme stresses and weather conditions while minimizing weight to maximize efficiency. Ultimately, fiber reinforced plastic rods represent a fusion of advanced engineering and reliability, setting new standards across diverse industries. Their role is that of an enabler, paving the way for innovative designs and long-lasting solutions. As industry requirements evolve, one can anticipate further advancements in FRP technology, driving even greater adoption rates. Through firsthand experience, comprehensive expertise, and unwavering authority in the field, it’s evident that FRP rods are not only a practical solution but also a testament to the relentless pursuit of engineering excellence.

Share

Next:

Latest news

-

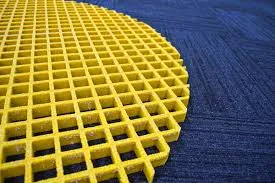

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024