loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Uses of Fiber Reinforced Polymer Rebar in Construction Applications and Benefits

Fiber Reinforced Polymer (FRP) rebar has become a revolutionary material in the construction industry, especially in strengthening and reinforcing concrete structures. As an alternative to traditional steel rebar, FRP rebar is composed of a composite material that combines high-strength fibers, such as carbon or glass, with a polymer matrix. This combination offers numerous advantages that enhance the performance and longevity of concrete structures.

One major benefit of FRP rebar is its corrosion resistance. Traditional steel rebar is prone to rust and corrosion when exposed to moisture and chloride ions, leading to structural deterioration and increased maintenance costs. In contrast, FRP rebar does not corrode in harsh environments, making it an ideal choice for projects in coastal areas or where de-icing salts are used. This durability significantly reduces lifetime maintenance and repair expenditures.

.

In addition to its physical properties, FRP rebar offers excellent tensile strength, providing effective reinforcement for various concrete structures. Its high strength-to-weight ratio means that designs can be optimized without compromising safety or reliability. This feature is particularly beneficial in applications such as bridge decks, parking garages, and precast concrete elements, where structural integrity is paramount.

fiber reinforced polymer rebar

When it comes to versatility, FRP rebar can be manufactured in a variety of shapes and sizes to meet specific project requirements. This adaptability allows engineers and architects to create innovative designs without being constrained by the limitations of traditional materials. Furthermore, the non-magnetic properties of FRP rebar make it suitable for applications in sensitive environments, such as hospitals and laboratories, where electromagnetic interference can be problematic.

The impact of FRP rebar is also evident in sustainable construction practices. As the construction industry becomes increasingly focused on environmental impact, FRP rebar presents an eco-friendly option. Its long lifespan and low maintenance requirements contribute to lower resource consumption over time. Additionally, the production process for FRP is generally less energy-intensive than that for steel, reducing the overall carbon footprint of construction projects.

In conclusion, Fiber Reinforced Polymer rebar offers a compelling alternative to traditional steel reinforcement in concrete construction. With its corrosion resistance, lightweight characteristics, high tensile strength, versatility, and sustainable advantages, FRP rebar is well-equipped to enhance the durability and performance of modern infrastructure. As more engineers recognize the benefits of this innovative material, FRP rebar is likely to play an increasingly vital role in the future of construction.

-

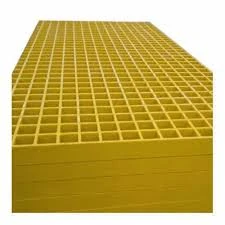

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024