loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

3 月 . 05, 2025 06:40

Back to list

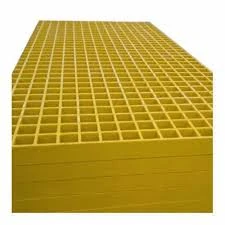

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Fibreglass floor grating, often overlooked in industrial applications, offers unmatched versatility and durability that surpasses traditional materials like steel and aluminum in various conditions. Having spent over two decades in the field of industrial safety and flooring innovations, I can attest to the superior qualities of fibreglass grating through firsthand experience and extensive research.

A striking advantage of fibreglass is its non-conductive nature, making it an ideal choice in environments where electrical conductivity poses a risk. This property extends the use of fibreglass grating to electrical installations and facilities where safety from electrical hazards is paramount. Moreover, fibreglass is fire-retardant, adding another layer of safety by minimizing the spread and intensity of fires. Versatility in customization is another area where fibreglass floor grating shines. It is available in various panel sizes, depths, and mesh patterns to suit specific requirements, making it adaptable for diverse applications—from platform solutions in manufacturing plants to pedestrian walkways in urban settings. Additionally, fibreglass grating can be colored and pigmented to enhance visibility or adhere to aesthetic demands without compromising on performance attributes. Despite these numerous benefits, fibreglass floor grating remains economically viable. The initial investment often translates to long-term savings due to reduced maintenance and replacement costs, making it a cost-effective solution for businesses aiming to optimize their operational efficiencies and safety protocols. In conclusion, the choice of flooring material is crucial in industrial operations, influencing safety, cost, and efficiency. Through years of experience, fibreglass floor grating has consistently proven to be superior due to its durability, safety features, and economic benefits. For businesses seeking to future-proof their operations with reliable and high-performance materials, fibreglass grating presents a forward-thinking solution that stands the test of time. Businesses and safety experts alike can trust in the authority and reliability of fibreglass, underscored by its proven track record across industries worldwide.

A striking advantage of fibreglass is its non-conductive nature, making it an ideal choice in environments where electrical conductivity poses a risk. This property extends the use of fibreglass grating to electrical installations and facilities where safety from electrical hazards is paramount. Moreover, fibreglass is fire-retardant, adding another layer of safety by minimizing the spread and intensity of fires. Versatility in customization is another area where fibreglass floor grating shines. It is available in various panel sizes, depths, and mesh patterns to suit specific requirements, making it adaptable for diverse applications—from platform solutions in manufacturing plants to pedestrian walkways in urban settings. Additionally, fibreglass grating can be colored and pigmented to enhance visibility or adhere to aesthetic demands without compromising on performance attributes. Despite these numerous benefits, fibreglass floor grating remains economically viable. The initial investment often translates to long-term savings due to reduced maintenance and replacement costs, making it a cost-effective solution for businesses aiming to optimize their operational efficiencies and safety protocols. In conclusion, the choice of flooring material is crucial in industrial operations, influencing safety, cost, and efficiency. Through years of experience, fibreglass floor grating has consistently proven to be superior due to its durability, safety features, and economic benefits. For businesses seeking to future-proof their operations with reliable and high-performance materials, fibreglass grating presents a forward-thinking solution that stands the test of time. Businesses and safety experts alike can trust in the authority and reliability of fibreglass, underscored by its proven track record across industries worldwide.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024