loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 17, 2025 00:33

Back to list

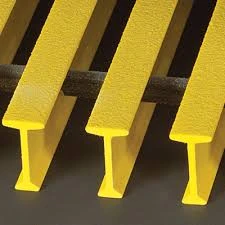

fibreglass grating

Fibreglass grating, often known for its superior qualities compared to traditional materials, is a groundbreaking solution that continues to revolutionize industries worldwide. With a robust combination of strength, flexibility, and corrosion resistance, it has become an indispensable material, evolving from its origins into a trusted component within diverse sectors. Let's delve into why fibreglass grating sets itself apart and explore the experiences shared by industries benefiting from its application.

Fibreglass grating's adaptability and versatility set it apart as a premium choice for innovating various applications. Its customizable nature allows for various sizes, shapes, and colors, meeting specific industry requirements without compromising its structural integrity. A leader in the architectural field praised its versatility, incorporating it into designs that reconcile both aesthetic appeal and functional necessity, underscoring the material's transformative potential in modern architecture. The confidence in choosing fibreglass grating extends to compliance with international standards. Meeting and often exceeding ASTM (American Society for Testing and Materials) and OSHA (Occupational Safety and Health Administration) standards, it assures users of its reliability and performance. Trust from industry authorities further substantiates its credibility as a material of choice, providing assurance to engineers and architects committed to maintaining high standards of quality and safety. On the forefront of sustainable materials, fibreglass grating is also seen as an environmentally friendly alternative. Its longevity minimizes the frequency of replacements, and its inert nature means it doesn’t produce pollutants over time. Environmental consultants emphasize the importance of such sustainable materials, advising industries to consider fibreglass grating not only for its performance but also for its reduced environmental impact, aligning business practices with global sustainability goals. In conclusion, fibreglass grating stands out for its extensive capabilities and widespread approval across several industries. Its robust qualities of strength, safety, adaptability, and environmental friendliness establish it as a trailblazer in innovative material solutions. With compelling evidence from industry leaders and adherence to global standards, fibreglass grating proudly maintains its status as a trusted, authoritative choice. As industries continue to evolve, embracing materials like this not only enhances operational efficiency but also reinforces a commitment to safety, sustainability, and excellence.

Fibreglass grating's adaptability and versatility set it apart as a premium choice for innovating various applications. Its customizable nature allows for various sizes, shapes, and colors, meeting specific industry requirements without compromising its structural integrity. A leader in the architectural field praised its versatility, incorporating it into designs that reconcile both aesthetic appeal and functional necessity, underscoring the material's transformative potential in modern architecture. The confidence in choosing fibreglass grating extends to compliance with international standards. Meeting and often exceeding ASTM (American Society for Testing and Materials) and OSHA (Occupational Safety and Health Administration) standards, it assures users of its reliability and performance. Trust from industry authorities further substantiates its credibility as a material of choice, providing assurance to engineers and architects committed to maintaining high standards of quality and safety. On the forefront of sustainable materials, fibreglass grating is also seen as an environmentally friendly alternative. Its longevity minimizes the frequency of replacements, and its inert nature means it doesn’t produce pollutants over time. Environmental consultants emphasize the importance of such sustainable materials, advising industries to consider fibreglass grating not only for its performance but also for its reduced environmental impact, aligning business practices with global sustainability goals. In conclusion, fibreglass grating stands out for its extensive capabilities and widespread approval across several industries. Its robust qualities of strength, safety, adaptability, and environmental friendliness establish it as a trailblazer in innovative material solutions. With compelling evidence from industry leaders and adherence to global standards, fibreglass grating proudly maintains its status as a trusted, authoritative choice. As industries continue to evolve, embracing materials like this not only enhances operational efficiency but also reinforces a commitment to safety, sustainability, and excellence.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024