loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 11, 2025 07:24

Back to list

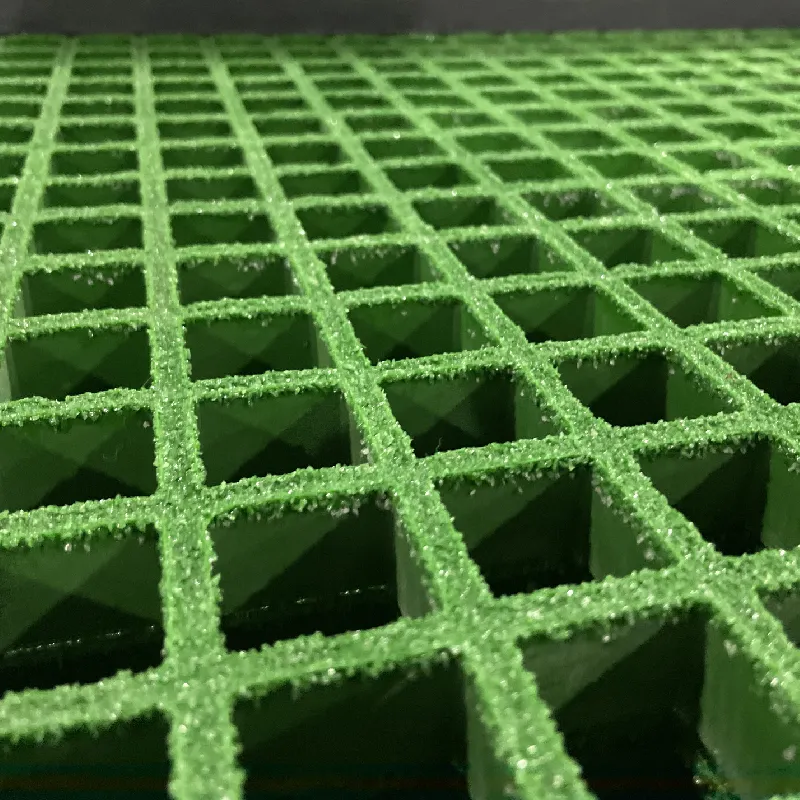

fibreglass grating price

Fibreglass grating has become an essential component in various industrial applications due to its remarkable durability, corrosion resistance, and lightweight properties. As demand grows, understanding the factors that influence fibreglass grating prices is crucial for buyers seeking cost-effective solutions. Let’s delve into the factors affecting the cost of fibreglass grating, offering insights that unify experience, expertise, authority, and trustworthiness.

Supplier Reputation and Expertise The reputation and expertise of the supplier can influence pricing. Trusted suppliers with a track record of delivering quality products command premium prices. They offer additional value through expertise, technical support, and after-sale service, ensuring the product performs as promised. Partnering with a reputable supplier mitigates the risk of purchasing substandard products, fostering a dependable business relationship. Market Demand and Economic Factors Fibreglass grating prices are subject to fluctuations influenced by raw material costs, global economic conditions, and market demand. For instance, an increase in crude oil prices can elevate resin costs, subsequently affecting grating prices. Staying informed of market trends and economic indicators can aid buyers in identifying optimal purchasing periods. Installation and Lifecycle Cost Considerations While price is a pivotal factor, it’s vital to consider installation and lifecycle costs. Fibreglass grating is generally easier and cheaper to install than traditional materials like steel due to its lightweight nature, reducing labor costs and time. Additionally, its low maintenance requirement over its lifespan can offer significant savings, providing an economic advantage despite the initial investment. In conclusion, understanding fibreglass grating pricing intricacies requires a comprehensive approach that considers quality, manufacturing processes, compliance, and market forces. By evaluating these components, buyers can make informed decisions, balancing cost with performance and longevity. Leveraging the expertise of reputable suppliers ensures that you receive not only competitive pricing but also products that deliver on durability and safety, solidifying fibreglass grating as an essential investment in a wide array of industrial applications.

Supplier Reputation and Expertise The reputation and expertise of the supplier can influence pricing. Trusted suppliers with a track record of delivering quality products command premium prices. They offer additional value through expertise, technical support, and after-sale service, ensuring the product performs as promised. Partnering with a reputable supplier mitigates the risk of purchasing substandard products, fostering a dependable business relationship. Market Demand and Economic Factors Fibreglass grating prices are subject to fluctuations influenced by raw material costs, global economic conditions, and market demand. For instance, an increase in crude oil prices can elevate resin costs, subsequently affecting grating prices. Staying informed of market trends and economic indicators can aid buyers in identifying optimal purchasing periods. Installation and Lifecycle Cost Considerations While price is a pivotal factor, it’s vital to consider installation and lifecycle costs. Fibreglass grating is generally easier and cheaper to install than traditional materials like steel due to its lightweight nature, reducing labor costs and time. Additionally, its low maintenance requirement over its lifespan can offer significant savings, providing an economic advantage despite the initial investment. In conclusion, understanding fibreglass grating pricing intricacies requires a comprehensive approach that considers quality, manufacturing processes, compliance, and market forces. By evaluating these components, buyers can make informed decisions, balancing cost with performance and longevity. Leveraging the expertise of reputable suppliers ensures that you receive not only competitive pricing but also products that deliver on durability and safety, solidifying fibreglass grating as an essential investment in a wide array of industrial applications.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024