loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

3 月 . 05, 2025 00:56

Back to list

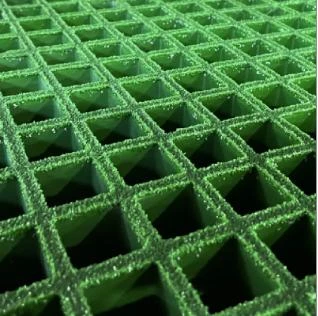

fibreglass mesh grating

Fibreglass mesh grating, a robust and versatile construction material, has become indispensable in a variety of industrial and commercial applications. Recognized for its strength, lightweight nature, and corrosion resistance, this technologically advanced product is transforming the way we approach infrastructure development.

In-depth knowledge of the specific mechanical properties of fibreglass grating is crucial for optimizing its applications. The grating's load-bearing capabilities, determined by its mesh size and thickness, can be specified to match particular structural needs. This allows engineers and architects to incorporate fibreglass mesh grating effectively into designs, ensuring both structural integrity and aesthetic value. The long-term cost effectiveness of fibreglass mesh grating cannot be overstated. While the initial investment may be comparable to metal alternatives, the reduction in maintenance, repairs, and replacement needs translates to significant savings over time. This makes it a financially sound investment for industries looking to reduce lifecycle costs. The environmental impact of fibreglass mesh grating also contributes to its growing popularity. Many manufacturers now focus on sustainable production methods, using recyclable materials and eco-friendly resins. This commitment to sustainability aligns with global trends towards green building practices and environmentally responsible construction. Fibreglass mesh grating's role in modern construction is further solidified by its aesthetic versatility. Available in various colors and finishes, it allows for creative architectural designs while maintaining functionality. This aspect is particularly valuable in public spaces and commercial developments, where visual appeal is as important as structural performance. In summary, fibreglass mesh grating represents a blend of innovative engineering, practical design, and cost-effective solutions. Its strength, adaptability, safety features, and environmental benefits make it an unparalleled choice for modern infrastructure projects. As industries continue to evolve, the use of high-quality fibreglass mesh grating will undoubtedly play a pivotal role in setting new standards for safety, efficiency, and sustainability.

In-depth knowledge of the specific mechanical properties of fibreglass grating is crucial for optimizing its applications. The grating's load-bearing capabilities, determined by its mesh size and thickness, can be specified to match particular structural needs. This allows engineers and architects to incorporate fibreglass mesh grating effectively into designs, ensuring both structural integrity and aesthetic value. The long-term cost effectiveness of fibreglass mesh grating cannot be overstated. While the initial investment may be comparable to metal alternatives, the reduction in maintenance, repairs, and replacement needs translates to significant savings over time. This makes it a financially sound investment for industries looking to reduce lifecycle costs. The environmental impact of fibreglass mesh grating also contributes to its growing popularity. Many manufacturers now focus on sustainable production methods, using recyclable materials and eco-friendly resins. This commitment to sustainability aligns with global trends towards green building practices and environmentally responsible construction. Fibreglass mesh grating's role in modern construction is further solidified by its aesthetic versatility. Available in various colors and finishes, it allows for creative architectural designs while maintaining functionality. This aspect is particularly valuable in public spaces and commercial developments, where visual appeal is as important as structural performance. In summary, fibreglass mesh grating represents a blend of innovative engineering, practical design, and cost-effective solutions. Its strength, adaptability, safety features, and environmental benefits make it an unparalleled choice for modern infrastructure projects. As industries continue to evolve, the use of high-quality fibreglass mesh grating will undoubtedly play a pivotal role in setting new standards for safety, efficiency, and sustainability.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

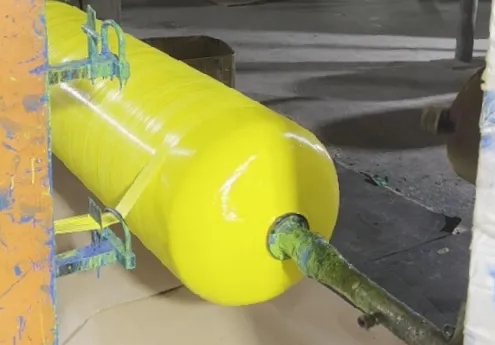

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024