loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 17, 2025 05:22

Back to list

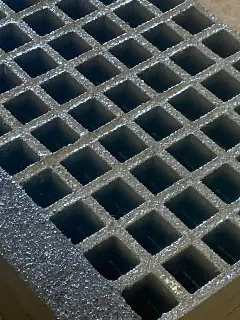

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

Fibreglass reinforced plastic (FRP) grating is an increasingly popular material finding its way into various industries and applications. With its unique composition, FRP grating offers a host of benefits that are not only innovative but also tailored to meet specific industry needs. This article delves into what makes FRP grating a superior choice, backed by real-world experience, industry expertise, and authoritative insights, ensuring you have trustworthy information.

Real-world applications have demonstrated FRP grating’s versatility. In a recent project within the offshore oil and gas sector, FRP was selected for its resilience against the corrosive sea environment and the added benefit of reducing overall platform weight. Similarly, municipal water treatment facilities have shifted towards FRP grating for its non-corrosive properties, ensuring cleanliness and durability, key factors in maintaining public health standards. These examples underline why FRP grating is increasingly viewed as a go-to solution in demanding settings. For those considering the switch to FRP grating, trustworthiness is further enhanced by stringent quality control measures during production. Manufacturers adhere to international standards, ensuring each piece of grating meets the necessary performance requirements. Additionally, suppliers often provide warranties that back the product’s long-term reliability, offering peace of mind to buyers wary of new materials. In conclusion, fibreglass reinforced plastic grating represents a forward-thinking approach to material selection in challenging environments. Its combination of durability, safety, and cost-effectiveness enables industries to enhance operational efficiency while reducing risks and maintenance demands. As industry experts continue to advocate for its use, and as real-world applications corroborate its benefits, FRP grating stands out not only as a wise investment but also as a leap towards more sustainable and innovative industrial practices.

Real-world applications have demonstrated FRP grating’s versatility. In a recent project within the offshore oil and gas sector, FRP was selected for its resilience against the corrosive sea environment and the added benefit of reducing overall platform weight. Similarly, municipal water treatment facilities have shifted towards FRP grating for its non-corrosive properties, ensuring cleanliness and durability, key factors in maintaining public health standards. These examples underline why FRP grating is increasingly viewed as a go-to solution in demanding settings. For those considering the switch to FRP grating, trustworthiness is further enhanced by stringent quality control measures during production. Manufacturers adhere to international standards, ensuring each piece of grating meets the necessary performance requirements. Additionally, suppliers often provide warranties that back the product’s long-term reliability, offering peace of mind to buyers wary of new materials. In conclusion, fibreglass reinforced plastic grating represents a forward-thinking approach to material selection in challenging environments. Its combination of durability, safety, and cost-effectiveness enables industries to enhance operational efficiency while reducing risks and maintenance demands. As industry experts continue to advocate for its use, and as real-world applications corroborate its benefits, FRP grating stands out not only as a wise investment but also as a leap towards more sustainable and innovative industrial practices.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024