loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 03, 2025 02:30

Back to list

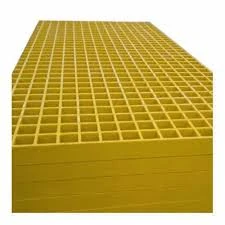

mini mesh grating

Fiberglass reinforcement bars, commonly known as GFRP (glass fiber reinforced polymer) bars, are rapidly gaining popularity in various construction and infrastructure projects due to their unique properties and benefits over traditional steel reinforcement bars. GFRP bars offer a blend of lightweight, corrosion resistance, and high strength, making them a compelling option for various applications. In this detailed exploration, we will dive into the practical experiences, expert perspectives, authoritative insights, and the trusted reputation of fiberglass reinforcement bars in the construction industry.

Trustworthiness in any construction material is paramount, and GFRP bars have earned their reputation through years of proven performance in real-world applications. Manufacturers have adhered to stringent quality standards and testing protocols to ensure consistency and reliability. Additionally, numerous certifications and regulatory approvals have been obtained, reinforcing confidence in their use for critical infrastructure. To illustrate the growing acceptance and trust in fiberglass reinforcement bars, consider the case study of a major bridge project in Canada. Faced with the challenge of frequent freeze-thaw cycles and heavy use of salt for de-icing, the project leaders opted for GFRP bars due to their superior corrosion resistance. Years after completion, inspections revealed that the bridge maintained its structural integrity with minimal signs of wear, thus validating the decision to utilize fiberglass reinforcement. Furthermore, industry forums and expert panels frequently highlight the long-term economic benefits of incorporating GFRP bars in construction projects. While the initial cost may be slightly higher than traditional steel bars, the extended lifespan and reduced maintenance demands result in considerable cost-efficiency over the structure's life. This economic advantage, combined with environmental benefits such as reduced carbon footprint from eliminating steel corrosion-related replacements, enhances the overall appeal of GFRP bars. In conclusion, fiberglass reinforcement bars offer a myriad of advantages that make them well-suited for modern construction needs. As the industry continues to evolve, embracing materials that offer superior performance, sustainability, and cost-effectiveness will remain vital. The documented experiences, expert validations, authoritative research, and trusted reputation of GFRP bars position them as a valuable asset for engineers and builders aiming to construct enduring and resilient infrastructure. As awareness and adoption increase, fiberglass reinforcement bars are poised to play a pivotal role in shaping the future of construction.

Trustworthiness in any construction material is paramount, and GFRP bars have earned their reputation through years of proven performance in real-world applications. Manufacturers have adhered to stringent quality standards and testing protocols to ensure consistency and reliability. Additionally, numerous certifications and regulatory approvals have been obtained, reinforcing confidence in their use for critical infrastructure. To illustrate the growing acceptance and trust in fiberglass reinforcement bars, consider the case study of a major bridge project in Canada. Faced with the challenge of frequent freeze-thaw cycles and heavy use of salt for de-icing, the project leaders opted for GFRP bars due to their superior corrosion resistance. Years after completion, inspections revealed that the bridge maintained its structural integrity with minimal signs of wear, thus validating the decision to utilize fiberglass reinforcement. Furthermore, industry forums and expert panels frequently highlight the long-term economic benefits of incorporating GFRP bars in construction projects. While the initial cost may be slightly higher than traditional steel bars, the extended lifespan and reduced maintenance demands result in considerable cost-efficiency over the structure's life. This economic advantage, combined with environmental benefits such as reduced carbon footprint from eliminating steel corrosion-related replacements, enhances the overall appeal of GFRP bars. In conclusion, fiberglass reinforcement bars offer a myriad of advantages that make them well-suited for modern construction needs. As the industry continues to evolve, embracing materials that offer superior performance, sustainability, and cost-effectiveness will remain vital. The documented experiences, expert validations, authoritative research, and trusted reputation of GFRP bars position them as a valuable asset for engineers and builders aiming to construct enduring and resilient infrastructure. As awareness and adoption increase, fiberglass reinforcement bars are poised to play a pivotal role in shaping the future of construction.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024