loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Applications of Fiber-Reinforced Plastic Grating in Modern Industries and Infrastructure

Fiber Reinforced Plastic Grating A Sustainable Solution for Modern Infrastructure

In recent years, the construction industry has witnessed a significant shift towards sustainable materials that offer durability, lightweight characteristics, and low maintenance needs. One such innovative material that has gained traction is Fiber Reinforced Plastic (FRP) grating. FRP grating combines the strength of fiber reinforcements with the versatility of plastic, making it an ideal solution for a wide range of industrial and commercial applications.

What is Fiber Reinforced Plastic Grating?

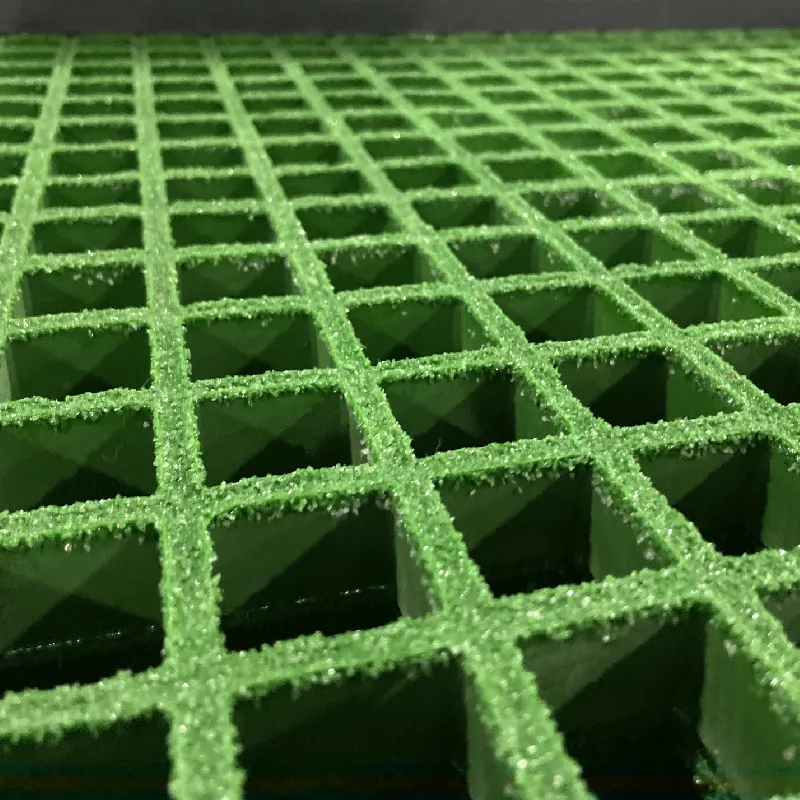

Fiber Reinforced Plastic is a composite material made from a polymer matrix that is reinforced with fibers, typically glass or carbon. The process of manufacturing FRP involves combining these fibers with a resin, which is then molded into various forms, including grating panels. This results in a product that not only boasts remarkable strength-to-weight ratios but also excellent resistance to corrosion, chemicals, and UV exposure.

FRP grating is available in various designs and configurations, making it suitable for diverse applications ranging from walkways, flooring, and platforms to industrial applications like chemical processing and waste treatment facilities.

Advantages of FRP Grating

1. Corrosion Resistance One of the most significant advantages of FRP grating is its exceptional resistance to corrosion. Unlike traditional materials such as steel or aluminum, FRP does not rust or degrade when exposed to harsh chemicals or moisture. This property makes it an ideal choice for environments prone to chemical spills or marine conditions.

2. Lightweight FRP grating is much lighter than steel, which simplifies installation and reduces transportation costs. Less weight means that structures can be designed using lighter supports, potentially lowering overall construction costs.

3. Durability The fiberglass reinforcement offers high tensile strength, allowing the grating to withstand heavy loads and impacts without deformation. This durability ensures a longer lifespan with minimal maintenance, reducing the need for replacements and repairs over time.

fibre reinforced plastic grating

5. Design Flexibility The manufacturing process of FRP allows for customization in terms of size, color, and surface patterns. This flexibility enables architects and designers to create aesthetically pleasing solutions that meet specific application requirements.

Applications of FRP Grating

FRP grating finds application in a wide variety of sectors

- Industrial Facilities In manufacturing plants, FRP grating is used for walkways, platforms, and stairways, providing safe access while reducing slips and falls, thanks to its slip-resistant surface. - Wastewater Treatment Given its corrosion resistance, FRP grating is extensively used in wastewater treatment facilities where it can withstand harsh chemicals and wet conditions without deteriorating.

- Marine Applications FRP grating is ideal for docks, piers, and boat ramps, as it can resist saltwater corrosion and provide a secure footing in slippery environments.

- Food Processing In food and beverage industries, FRP grating is favored for its ease of cleaning, resistance to bacteria harboring, and compliance with health regulations.

Sustainability Considerations

In today’s environmentally conscious world, the sustainability of materials is an essential consideration. FRP grating can contribute to green building initiatives as it often utilizes recyclable materials and reduces the need for frequent replacements. Furthermore, the energy costs associated with manufacturing and transporting FRP are generally lower than those for traditional materials, making it a more eco-friendly choice.

Conclusion

As industries continue to evolve and prioritize sustainability alongside functionality, Fiber Reinforced Plastic grating stands out as a robust solution. Its combination of lightweight, corrosion resistance, durability, and design flexibility has positioned it as a preferred material across various applications. By opting for FRP grating, businesses not only enhance safety and efficiency in their operations but also contribute to a more sustainable future. As awareness of such materials grows, it is likely that FRP grating will become an even more integral part of modern infrastructure.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024