loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 14, 2025 12:47

Back to list

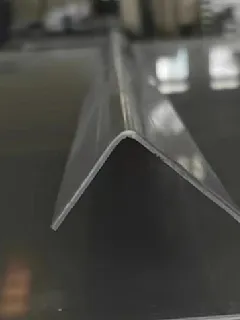

fibre reinforced plastic tanks and vessels

Fibre reinforced plastic (FRP) tanks and vessels are transforming the landscape of industrial storage solutions. These advanced composite materials, born from the strategic melding of robust fibres like glass or carbon with resilient plastic matrices, stand out for their unparalleled durability and flexibility. The integration of expertise across materials science and engineering has culminated in a product that promises not just longevity, but also performance excellence across various applications.

The authority of FRP technology is further reinforced by stringent adherence to international quality standards and certifications. Industry bodies and regulatory organizations recognize FRP products for meeting high safety and environmental criteria, reinforcing trust among end-users. Engineers and architects often prefer FRP solutions to traditional materials, relying on verified performance data and test results that underline their reliability and safety in critical applications. In terms of maintenance, FRP excels with low upkeep requirements. Unlike metal tanks that require regular painting or coatings to prevent corrosion, FRP tanks only require routine inspection, translating to reduced labor and operational costs over time. This maintenance advantage not only minimizes potential downtime but also maximizes operational efficiency—real benefits for industries that demand consistent, reliable performance. Environmental considerations are increasingly driving industrial decisions, and here too, FRP tanks and vessels serve as a sustainable option. The materials used in FRP are often recyclable, and their long lifespan means fewer replacements, thus reducing material waste and the energy footprint associated with frequent manufacturing processes. In conclusion, fibre reinforced plastic tanks and vessels stand as the epitome of modern storage solutions, offering unmatched benefits in terms of durability, customization, and cost-efficiency. Their successful integration into various industry sectors is a testament to their superior design and functionality. As a trusted resource in the field, they represent the future of industrial storage—a future marked by innovative engineering and sustainable practices. For industries looking to enhance their storage capabilities, investing in FRP solutions is not just a choice; it is a strategic decision toward operational excellence and environmental stewardship.

The authority of FRP technology is further reinforced by stringent adherence to international quality standards and certifications. Industry bodies and regulatory organizations recognize FRP products for meeting high safety and environmental criteria, reinforcing trust among end-users. Engineers and architects often prefer FRP solutions to traditional materials, relying on verified performance data and test results that underline their reliability and safety in critical applications. In terms of maintenance, FRP excels with low upkeep requirements. Unlike metal tanks that require regular painting or coatings to prevent corrosion, FRP tanks only require routine inspection, translating to reduced labor and operational costs over time. This maintenance advantage not only minimizes potential downtime but also maximizes operational efficiency—real benefits for industries that demand consistent, reliable performance. Environmental considerations are increasingly driving industrial decisions, and here too, FRP tanks and vessels serve as a sustainable option. The materials used in FRP are often recyclable, and their long lifespan means fewer replacements, thus reducing material waste and the energy footprint associated with frequent manufacturing processes. In conclusion, fibre reinforced plastic tanks and vessels stand as the epitome of modern storage solutions, offering unmatched benefits in terms of durability, customization, and cost-efficiency. Their successful integration into various industry sectors is a testament to their superior design and functionality. As a trusted resource in the field, they represent the future of industrial storage—a future marked by innovative engineering and sustainable practices. For industries looking to enhance their storage capabilities, investing in FRP solutions is not just a choice; it is a strategic decision toward operational excellence and environmental stewardship.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024